While the fast expansion of the direct-to-film print market is on the one hand good news for the industry, this growth has left the sector rather commoditised, with huge competition in this area. LFR explores what companies in this market can do to stand out, ensure they move to the front of the pack and, ultimately, succeed.

Direct-to-film (DTF) printing is, in the grand scheme of things, still a new technology. DTF has only been around for two decades or so but has already has a major impact in the industry as a whole, with companies around the world using DTF machines and methods to produce all manner of printed applications.

The explosion of DTF’s popularity, coupled with the availability of DTF technology, has seen the market grow at an alarming rate. However, going hand in hand with this is the number of companies offering DTF, which has in turn led to commoditisation within the market, with those in the sector facing huge levels of competition for the most valuable work.

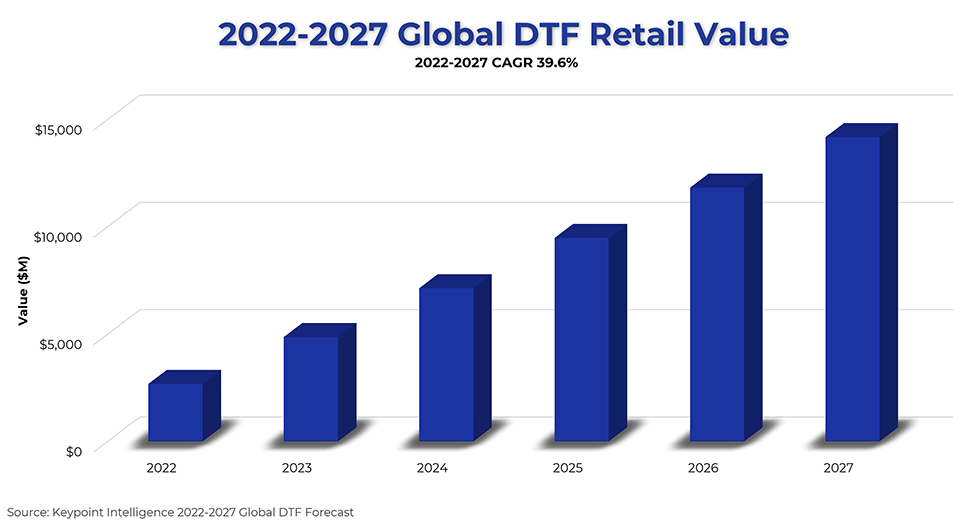

Let’s begin with some stats if we may. Glancing at the latest report from Keypoint Intelligence, in 2022, the estimated print volume for DTF was some 190 million sq m; by 2027, this is likely to be somewhere around 1.00 billion sq m.

In terms of value, the same report placed the retail value of the DTF market at $2.78bn in 2022, whereas by 2027, this is forecast to be somewhere around the $14.00bn mark. If that is not enough to capture the interest of those on the periphery looking to move into this sector, or indeed those in the market eying new growth opportunities, then what will?

“The adoption rate of DTF is unlike anything the decorated apparel industry has seen,” the report said. “DTF unit placements were approximately 44.5% of all DTF, direct-to-garment, and toner transfer unit placements in 2022. By 2027, DTF unit placements are projected to be 64.4% of all such unit placements.”

Adding to this, the report said that in 2022, there were approximately 9,082 DTF hardware machines in place around the world. Fast-forward to 2027, and this number could be as high as almost 15,000 as more companies look for a piece of the action. The majority of these machines are likely to be two-head models, with four-head devices set to account for around one quarter of the market.

Can DTF still be a profitable business?

With this in mind, one cannot help but ask the question: can DTF still be a profitable business? Well, the short, and positive, answer is Yes it can. However, print service providers (PSPs) need to be clever about how they offer this service and produce work using DTF technology in order to be profitable and enjoy high margins in the longer run.

Easy access to DTF machinery has driven growth in the market during recent years. Cheap kit from China means pretty much anyone can afford to offer some sort of DTF service to their customers; and while this is good for those seeking to diversify, it has created an overstocked market.

Interestingly, Keypoint Intelligence makes direct reference to this issue in its report. It stated: “The DTF market is still in its infancy, and there is a lot of turbulence among providers of DTF hardware. DTF has had a drastically compressed development path, with milestones and hurdles that mirror the early days of direct to garment (DTG) inkjet.”

So, what can you do to ensure you stand out from this crowd and attract the attention of the most valuable customers? The easy answer is to offer a better service than anybody else.

For customers seeking quick and cheap work where quality is not a huge issue, then they are spoilt for choice and can shop around for the best deal. However, customers that have their eye on quality will want to work with PSPs that can deliver. And to do this, you need to be working with highest quality machinery from trusted brands.

Again, Keypoint Intelligence steers companies in the right direction, saying that among the large number of vendors offering DTF solutions - more than 50 - there is notable movement from well-known brands such as Brother, Epson, Mimaki, and Roland, all of which are now introducing their own printers.

“Continuously monitor the market conditions and review your strategies based on real-time data and evolving trends,” the report advised.

Roland DG recently launched their entry-level soution, the VersaSTUDIO BY-20, a desktop DTF printer with sheet cut and contour-cutting capabilities.

Why exactly is DTF so popular?

Before getting into what you should be looking for in a quality DTF machine, let us first look at the actual technology of DTF and why this has become such a popular option not only for PSPs but also the customer.

Firstly, DTF is an easy method to learn and master. Printing with water-based pigment inks on polyethylene terephthalate (PET) film is very much like printing onto paper, which is something all printers know, or certainly should know, how to do. It is a straightforward process, does not contain many elements and can be performed in a small space, thus opening up its use to all types of printing companies.

Next, the speed of DTF printing means PSPs can turn round work quickly. Once the film has been printed, it can be stored until required in the transfer process, not only allowing PSPs to prepare work in advance ahead of busier periods but removing the need for double white or CMYK printing as required when working with other printing methods.

Then there is the cost, with this appealing to many businesses looking to maximise profit on all jobs. Despite the additional cost of film and powder, DTF printing can often be the most cost-effective method of printing, offering an economic gains benefit to PSPs of all sizes.

Finally, the sheer scope of applications you can produce using DTF printing methods opens up all manner of markets to print companies. From common apparel work such as T-shirts, hoodies and sportswear to promotional items and even interior décor, there is plenty to explore with DTF.

The DTG dilemma

When discussing DTF, it is only right to also reference DTG technology. After all, both take a “direct” approach to printed work, with some saying DTG offers an even more direct route by printing straight onto the garment.

Of course, this removes the need for the transfer process, as well as the need to work with films and powders. However, the argument for DTF over DTG remains strong. In fact, even after having to purchase these extra elements, the final cost to produce a T-shirt with DTF is marginally cheaper than when working with DTG machines.

Next, when working with DTF, this does not require any sort of pre-treatment, with DTF suitable for use with many fibre types such as polyester, cotton, nylon, and even mixed fibre blends.

DTF manufacturers and suppliers also say DTF printing allows users to achieve a much wider colour range, thus opening up more options for customers. Then there is the actual quality of the print; DTF and its transfer process offers much higher accuracy when it comes to finer detail such as lines and small fonts, producing a much sharper finish than DTG.

Add in that DTF-printed garments perform better when it comes to elasticity and stretchability, and the advantages are clear to see.

So, what next?

These points are based on where the market is now and the machines currently available to PSPs. But what about moving forward into the future? At the recent 2024 FESPA Global Print Expo, we were treated to some of the latest innovations in the world of DTF, with manufacturers and suppliers in attendance promising lots of exciting developments as the market continues to grow.

From what we saw at FESPA 2024, and what we will likely experience at Drupa in a few weeks, one of the overarching factors impacting not only the DTF market but all areas of print, is sustainability. With customers demanding increasingly environmentally friendly print, manufacturers are having to respond – and this is absolutely evident in the DTF sector.

Take Mimaki for example; the manufacturer has recently announced the launch of its new Mimaki TxF300-75, which incidentally offers the best of both worlds in terms of DTF and DTG printing. The machine can print onto cotton, polyester, and polyester blended materials, and on both light and dark coloured fabrics.

Featuring a two-year warranty as standard, the new printer uses Mimaki’s OEKO-TEX ECO PASSPORT certified ink, which the manufacturer said enables garment decorators to meet rising client demand for skin-friendly production and environmental commitments. Hybrid Services, the exclusive UK and Ireland Mimaki distributor, showcased the machine for the first time at this year’s Sign & Digital UK back in February.

The new model aims to build on the early success of the Mimaki DTF range, which launched last year. Sales across the EMEA region of the TxF150-75 model have already surpassed 300 units, with Mimaki saying that the latest machine offers a threefold speed gain over previous models and has been specifically designed to meet the needs of the professional volume garment decoration market.

“Recognising the rapidly growing popularity and satisfaction with the direct-to-film process, the TxF300-75 is now available alongside its hugely successful stablemate, the TxF150-75, to give even greater choice to those entering or expanding in the garment decoration market,” Hybrid sales director Andrew Gregory said. “Such is the stability of the technology; we’re delighted to be able to deliver the new TxF300-75 with an unprecedented two-year warranty.”

What are the experts saying?

Of course, Mimaki will wax lyrical about its latest DTF printer, and rightly so given the big increase in speed and the high-quality printed output that visitors were able to view at FESPA a month or so back. But what about opinion on the market as a whole? Where are we heading and what can printers do to ensure they can capture the most profitable work?

Incidentally, Marc Verbeem, Supervisor Product Management at Mimaki, was one of the many specialist staff on site at FESPA, overseeing demos of the new printer. Speaking with LFR, he said high demand for DTF solutions will continue over the coming years, saying that both customisation and personalisation will be key drivers behind this demand and growth.

He also makes reference to other key developments, such as the introduction of AI software, which he said simplifies design creation and opens up the market to even more people, including those not necessarily having the highest level of print skills.

“Even if you are a hobbyist, you can now produce a unique and personalised design without too much effort,” he said. “New DTF films that include gold, silver, glitter and reflective will push an even wider range of DTF products.

“Then there are more upcoming trends such as paper-based DTF media and powderless DTF, though these will need to prove themselves over the next few years.”

Marc admits that Mimaki is still fairly new to the DTF market, with its first DTF printer only being launched just over a year ago. However, with development fast moving - as seen with the new TxF300-75 - Mimaki is understanding more what customers want from their DTF machine, with the manufacturer continuing to monitor what is happening in the sector.

“There is a high demand for reliable and stable DTF solutions,” Marc said. “Customers are looking for systems that can provide unattended print that results in higher productivity. They are in need of higher productivity as the request for personalised items further increases.

“Sustainability is very important for us too, so we monitor the development of paper-based DTF media and powderless DTF closely.”

Phenomenal growth

Also championing DTF is RA Smart, which has partnered with Polytech to distribute its DTF solution since 2021. Incidentally, Polytech is one of the pioneers of DTF technology, developing the process with its patented powder application system.

Having witnessed first-hand the expansion of this market, Alex Mighall, Product Marketing Manager at RA Smart, said “phenomenal” growth in DTF is due to its technical advantages over other forms of garment decoration, highlighting how a plethora of different DTF platforms have been introduced to the marketplace over the past couple of years. He adds that the influx of big-name brands will only support further growth.

“Most of these systems, until very recently, have been coming from Chinese suppliers that have seen the potential in the DTF market,” Alex said. “It is therefore very important for any potential customer looking to invest in a DTF system to do their due diligence and satisfy themselves of the capabilities and reliability of any solution and be sure that the support structure is in place from the supplier channel offering the system.

“There is no doubt that DTF technology offers a fantastic solution to garment decoration but working with a reputable dealer is vitally important to ensure the inevitable learning curve associated with this relatively new technology is a smooth as possible.”

As to where the market is heading, RA Smart has picked up a general trend for DTF machinery that offers users a quicker turnaround for their customers as well as increasing versatility in the range of products that can be produced from one machine.

“The cost per print is also very attractive compared to alternative technologies such as DTG printers, particularly if printing onto dark colour garments where the latter requires a pretreatment and the cost of print is generally higher than that of DTF,” he said.

“We are now starting to see larger print providers investing in multiple machines and more productive machines and we think the requirement for more productive systems will continue to grow. Alongside the increased speed of printing systems, we now have the requirement for dedicated DTF cutters.”

On this, Alex sets out how RA Smart is working with Secabo on the new MultiCut Pro DTF cutter. The second generation of cutter, shown for the first time at FESPA 2024, is aimed at smaller businesses and will allow either an in-line or off-line solution.

What about higher volume DTF?

There was a huge DTF presence at the recent FESPA Expo in Germany, with higher volume solutions on show from some established brands.

Ricoh has announced what it describes as a ‘digital industrial garment decoration first’ in the form of the Pro D1600 direct-to-film printer and shaker/dryer system.

Kornit were also giving sneak previews of their pending powder-free DTF alternative, the Kornit Max Transfer, which will offer productivity of up to 150 garments per hour.

M&R were also exhibiting their Quatro industrial DTF system, featuring an eco-friendly water-based ink.

Could trade print be an option?

While there is unquestionably plenty of choice when it comes to higher level DTF machines, and more to come before we know it, perhaps you do not want to take the risk of high investment if you cannot be certain that such a move will pay off in the long term. And that is OK; after all, everyone needs to look after their pennies.

The other option for those seeking inroads into the DTF market is to work with a trade printer that offers such a service. Of course, this means having to give up a chunk of profit on each job, but it saves having to invest in and train on a new piece of kit and allows you to begin taking orders and delivering work straight away.

So, is it worth it? Well, this simply comes down to how much DTF you are expecting to do. If you already have work lined up with existing clients, have a good idea about where you will get more work from, and are fully versed in how to work with this technology, then perhaps take the plunge straight away. On the flip side, if you are new to the market and want to test the water before you fully emerge yourself in DTF, then consider a trade partnership to ease you into the market.

To sum up, there is plenty to be excited about when it comes to DTF. Not only does the technology allow you to produce all manner of printed work, but the speed at which this is evolving – and the number of heavy hitters getting involved by launching their own machines – suggests we can look forward to more growth, expansion and, again, excitement in what is already a highly active market.

Happy hunting.