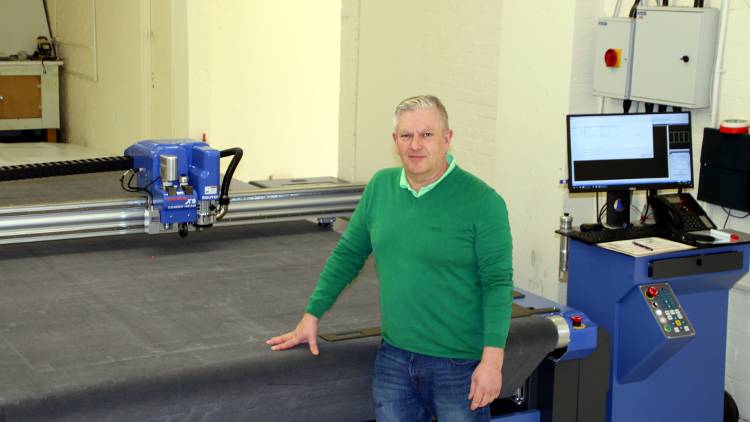

The Edmonton trade finisher for paper-based PoS display work originally set up to produce bunting, posters and direct mail. Now, it offers cardboard engineering and large format die cutting; packaging and assembly; mounting and fulfilment; distribution; warehousing and much more. The cardboard engineering specialist has always set its stall out by investing in state-of-the-art technology. Down the years this has included the world’s largest flat-bed Goldline die-cutter, Europe’s largest Bickers Gluejet system, a host of automatic gluing, hand-fed platen and large format laminating technology. To add diversity to the business, PPFS recently installed an AGFA Anapurna M2540FB large format digital printer and a DYSS X9-2230C digital cutter from AG/CAD.

Commenting upon the investment in the DYSS X9-2230C and the Anapurna, PPFS Director Annette Hobbs says: “Digital print jobs are increasingly requested in smaller quantities and we were losing this short run print and assembly work because the cost of conventional die-cutting was pricing us out of the equation. Projects with a run of less than 200 were typically too small to make die-cutting a viable option. We were losing work that we used to mount and die-cut, for example for smaller retailers, or jobs printed in multiple languages, therefore we had to look at ways we could offer our clients this service more competitively. At the same time, we wanted to expand into large-format digital print to open new markets – we knew that without a digital cutter alongside, a printer on its own wouldn’t be sufficient to retain the short run work we were losing.”

Why Buy The DYSS?

According to Annette Hobbs, the decision to purchase the DYSS was straightforward. As the Company Director recalls: “The AG/CAD solution won us over on two key factors. Firstly, we are a trade finishing company – all the leading businesses in our sector use AG/CAD’s KASEMAKE CAD software. It is the leading package and it is recognised as the industry standard for display work. AG/CAD are the developers of the software as well as suppliers of DYSS digital cutters, so why opt for another supplier’s cutter using inferior software?”

The DYSS is a Cut Above..

The other key factor behind choosing the DYSS X9-2230C was the cut quality. As Annette continues: “The second reason for selecting the DYSS was based on the fact that we conducted trials on all the leading cutting tables using E, B and EB flute boards as 80-90% of what we process is corrugated. None of the other machines could match the performance of the DYSS. Die-cutting historically delivers a better cut-quality than a digital cutter when processing these boards; this is because die-cutting has high precision, repeatability and superior creasing. With a digital cutting machine, the board is susceptible to cracking and splitting during the cutting and creasing process. Knife tools can show drag marks on the board, or rip, whilst creasing tools must apply the exact pressure to generate perfect creases. By no means were we prepared to compromise on the quality of our products; fortunately the DYSS X9 was far superior to the other machines we trialled. We couldn’t tell the difference between DYSS cut boards and our standard die-cut boards.”

….And The Benefits?

The immediate benefit is that projects with runs up to 200 can now be manufactured cost-effectively without the £400 to £500 cost of large die cutting tools. “This instantly makes us cost competitive, it eliminates the cost of dies and it reduces our lead-times. We can now turn jobs around immediately if required, without waiting 2-3 days for external suppliers to produce the die tools. Going forward, our die-cutting set-up and die costs will fall significantly, our lead-times have already fallen and we can also do samples on the X9. Additionally, we can undertake design work and offer consultancy advice as well as proving-out jobs prior to entering die-cut production. The DYSS also has a taping head that allows us to tape samples and test pieces instead of gluing them, which is a huge benefit for prototype work.”

Why Opt for the New DYSS X9?

The next generation 2.2m by 3.2m DYSS X9-2230C machine wasn’t just selected by the 25 employee company for its high speed capability or its enhanced drive technology and precision levels. For PPFS, it’s all about buying the very latest technology. As Annette continues: “In a few years, DYSS could introduce next generation tooling and we don’t want to be behind the curve. This new machine is completely modular; it allows us to upgrade elements and features at a later date. We can evolve the configuration of the machine to suit our business whilst being comfortable with the knowledge it is one of the fastest machines on the market.”

The X9 has a Combo-head configuration with a high-speed oscillating knife, high-frequency routing tool and creasing tools. Using the supplied K-CUT Vision System these tools all help guarantee the quality and accuracy levels that PPFS requires. The combination allows PPFS to process plastic, vinyl, corrugated, display board, Foamex PVC, Correx, foam core and more. “This machine gives us the potential to process a huge range of materials. Essentially, the DYSS gives us the ability to say ‘yes’ to just about anything the customer throws at us. At present, we’re doing a lot of PoS, FSDU’s and posters for cinemas, the home entertainment sector, supermarket and the health & beauty industry.”

“Since the DYSS was installed, we have been targeting more short-run digital print work as the machine gives us a clear edge over competitors when it comes to low volume, fast-turnaround work. Small run digital work has historically been 10% of our business, a percentage that had been in decline due to the cost constraints and limitations of traditional die-cut production over the years. The DYSS has rapidly recouped this dwindling element of the business and we are expecting significant growth in the short to mid-term future. This upturn is a credit to both the DYSS and the Anapurna.”