Since its launch in January 2012 James Gibbins’ company, exhibitionstands.co.uk, which trades as Stand4, has been steadily growing. Its website has become one of the top rankers in the Google listings as word-of-mouth recommendations gather interest, and repeat business keeps James’ team busy.

As its name suggests, James’ company provides a wide range of exhibition stands and display solutions. He said, “What we aim to do every time is put ourselves in our customers’ shoes. What kind of service would we expect if it was us making the purchase? Then we simplify the ordering and purchasing process. Our customers are busy people and the more we can do to help them the more they appreciate it.”

He continued, “An exhibition stand is important. It is the company’s ambassador during a show. It has to represent our customers in the public eye and that’s quite a responsibility for the stand manufacturer. We listen and advise if necessary, and our portfolio includes options ranging from pop-ups and roll-ups to portable displays, pop-up shops and sales booths. We also manufacture full, bespoke exhibition units on a hire or sale basis. We have units for indoor, outdoor and forecourt, and if the artwork is provided on time we can normally guarantee a 24-hour turnaround to customers throughout the UK and parts of Europe. Tell us what you need us to do and we can tell you how fast we can do it, or, sometimes, how we can provide something better.”

Exhibitionstands.co.uk was originally built by sub-contracting work out to select graphics providers around the region, but as demand grew that was no longer a viable option.

James explains, “We had previously met customers’ needs through the skills of sub-contract business partners, but that manufacturing model could only work within certain parameters. As demand has grown we have chosen to increase our in-house facilities to help us speed delivery and ensure the finished product always meets our strict quality standards, and, of course, that our customers are happy with the end result. That is the final benchmark for any supplier.”

Organic evolution

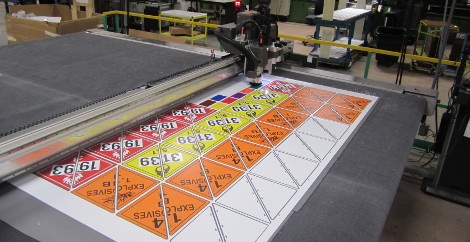

In August 2015 the workshops saw delivery of a Summa F1612 Pro flatbed cutter from CWE Solutions Ltd, a reseller for Summa’s UK distributor, ArtSystems. The choice had proved a simple one. James said, “We needed high quality cutting and creasing across a broad portfolio of materials and the only way to meet that need was to bring the facility in-house in an affordable way.

“We had seen the Summa in action and we knew it provided really great specifications for the money. It was a no-brainer to make the investment and it has already proven its worth, especially with regards to the increasing number of bespoke projects we are handling.”

Exhibitionstands.co.uk often has to demonstrate real flexibility with its customers, largely because it doesn’t deal with any specific industry sector. James explains, “One day we might be working with Bulmers Cider and the next with blu, the e-cigarette manufacturer. It is this kind of variety that is driving the increase in bespoke stand and pop-up shop manufacture, and is one of the reasons we needed the Summa F1612. As a result of our investment we have tightened turnaround times and quality control.”

James ascribes his company’s success to organic evolution based on service, including quality print, competitive pricing and a ‘tell not sell’ approach to marketing. He said, “People don’t want to feel they’re being sold to. They want to maximise their return for the budget they’ve allocated and don’t want to be seen as simply another cash cow ready for milking. Thanks to our portfolio we can accept projects from anyone, small traders or large corporate players, and provide solutions that match both their needs and their pockets.

“We enjoy the unusual request,” he continued. “For instance, we have built a pop-up shop in the shape of a double-decker London bus and provided special photographic booths that visitors can use to take souvenir shots at weddings. You’d think our work would see us spending most of our time at the big exhibition halls such as the NEC or ExCeL but that isn’t the case. We have created PoP units, coffee stalls and more. Variety is at the heart of our working day, and we love meeting a challenge.”

James hasn’t limited his company to purely exhibition work, it also has the facility to be a graphic and print provider, including large format printing, laminating and finishing, graphic design and print-ready artwork. It is also involved with 3D design and animation.

He concludes, “The Summa is our latest acquisition and thanks to it we will continue to grow our customer base and range of exhibition stand solutions. It will be interesting to see where we shall be in a year’s time.”

For more information visit www.exhibitionstands.co.uk.

For more information regarding CWE Solutions Ltd visit www.cwesolutions.co.uk.

Summa F1612 specifications:

Dimensions: 235 x 196 x 110cm (without roll support)

Media width: Up to 165cm

Cutting area: 160cm wide x 120cm long

Speed: Up to 1000mm/s

Summa’s award winning cutting tables are capable of cutting sheet and rigid materials as well as roll stock. Up to three tools can be inserted at any one time on the multi-module tool holder. Changing tools is quick and easy. Automatic tool recognition, combined with digital and mechanical depth and/or pressure control, ensures precision cutting on a wide variety of materials.

The F series base unit comes equipped with a drag module and Summa's optical camera marker recognition system for accurate contour cutting of printed flexible or rigid substrate materials.

Multiple material handling options ensure optimal workflow for roll, sheet and board material.

The Tangential module corresponds to a whole range of matching tools for cutting materials from vinyl to textiles to carpet, kiss-cutting the most demanding roll materials and creasing a wide range of cardboards.

The router module mills most materials used in the sign workshop, from hard foam PVC and acrylic to aluminium coated foam board.

For more information on the Summa range call ArtSystems on +44 (0)115 9380 380 or visit www.artsystems.co.uk.