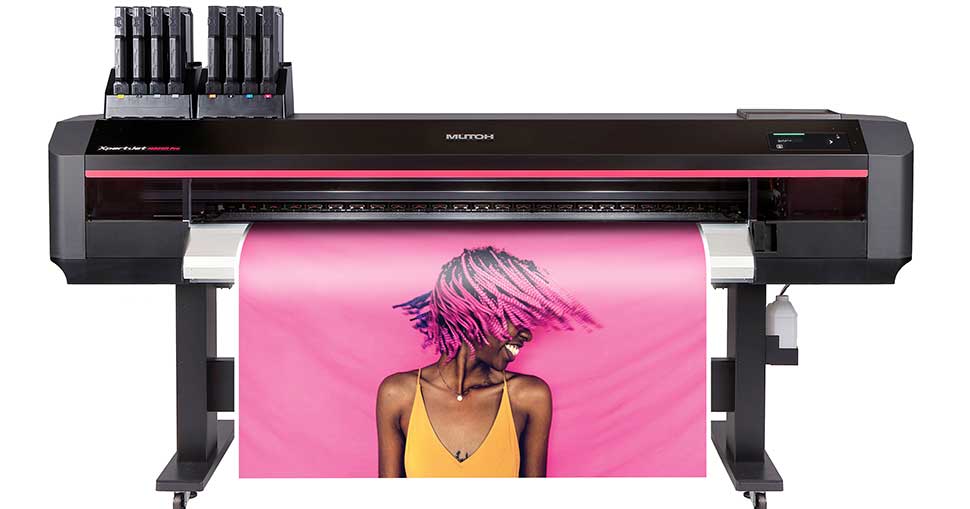

The new XPJ-1682SR Pro carries two AccuFine HD print heads, each with 3200 nozzles, a new weaving algorithm and Mutoh’s genuine VerteLith RIP software to deliver a significant improvement in both print quality and print speed. The XPJ-1682SRP is ideally suited for high productivity environments, delivering high quality production speeds up to 35 m²/h. The new printer also integrates automatic alignments to ensure uninterrupted production and consistent quality.

Particularly interesting to users is that the printer will be launched with Mutoh’s new MS51 quick dry CMYK inkset. Mutoh MS51 inks fulfill the requirements of today’s sign professionals with regards to indoor and outdoor signage applications, yet do not require health and safety pictograms and are also gBL free. As such they can be used in office, home and retail environments. Compared to traditional sign and display inks, they offer the same colour gamut, excellent gloss preservation and weather resistance, abrasion and chemical resistance with UV durability up to 3 years without lamination. There is also no additional printer maintenance required.

Mutoh MS51 inks are also GREENGUARD Gold certified. Certification was obtained for the category Wallpaper, which means that output can be used at full room coverage, even in sensitive environments such as schools and hospitals.

Engineered and manufactured in Japan, the XPJ-1682SR PRO brings together the very best of Mutoh proprietary technologies for drop accuracy and therefore print quality:

- Mutoh’s new AccuFine HD extra-wide 3200 nozzle print head technology

- i-screen weaving, Mutoh’s fourth generation Intelligent Interweaving technology

- Mutoh’s genuine VerteLith RIP software

These technologies have been designed to work seamlessly together to give users the most accurate drop-placement in the industry and they are all on-board the new XPJ-1682SR PRO. The new print head guarantees improved droplet quality, along with more accurate drop positioning. The i-screen weaving algorithms as implemented in the firmware of the Mutoh Pro class engines exploit the increased droplet quality to suppress banding even more. The VerteLith proprietary Mutoh screening, called Clear Tone, employs the improvements to the printer and print head to deliver even better gradients and skin tones, even in 4-colour setup, free of any noise.

Key fact is that users will gain significant quality and speed advantages over the previous models in all production print modes.

The XPJ-1682SR Pro twin head printer is an addition to Mutoh’s existing XPJ-1341SRP and XPJ-1641SRP single head models released in January. The printer will be marketed by Mutoh Europe throughout the EMEA business area through its existing network of certified distributors.

Mutoh XpertJet 1682SR Pro – Product Highlights

- 2 new AccuFine HD 3200 nozzle print heads on board; drop mass range 3.44 pl-17.71 pl.

- New generation i-screen weaving technology suppresses banding even further.

- New VerteLith Clear Tone Screening to deliver the best gradients and skin tones.

- New MS51 inkset : free of gBL, no hazard or safety pictograms, GREENGUARD Gold certified.

- Mutoh’s genuine VerteLith RIP Software :

Built around Harlequin RIP Core

- Straightforward & powerful user interface

- Simple workflow

- ICC substrate profiling included

Powerful preview functions to reduce errors and waste :

- Soft proof before printing

- What-you-see-is-what-you-get RIP previe

- Workflow efficiency & finishing tools (trim marks, grommets, automated and manual

- tiling, step & repeat functionality, accurate multi page PDF processing, …)

- Mutoh companion workflow software for print to cut applications

- Motorised take-up systems: 30 kg, 40 kg, 100 kg

Unrivalled user assistance to save time and waste :

- Automated bi-dir alignment.

- Automated media feed adjust.

- Automated media roll length management through bar code print/scan.

- Nozzle Area Select allows disabling of nozzle areas on the head to continue printing.

The 1682SR-P can be equipped with an optional automated nozzle check unit : printer will automatically detect missing nozzles, attempt recovery via cleaning and, if needed, automatically activate the Nozzle Area Select feature to continue production, without the need of an operator intervention.