Of the 20 materials listed in the study, the most commonly used in UV printing is Plastic – with 75% of those polled using it at least once – closely followed by Wood (64%), PVC (62%) and Metal (54%). These materials were also the ‘biggest growers’ in 2020, with just under a fifth (18%) of those polled reporting an increase in demand for PVC, followed by Plastic (17%), Wood, (14%) and Metal (9%).

Similarly, in terms of frequency of use, the same four materials are clearly leading the pack with over two thirds (43%) of those polled printing on Plastic at least once a week, followed by PVC (40%), Metal (26%) and Wood (25%). A quarter of printers expect this frequency to increase most for Plastics (25%) in 2021, followed by Metal (24%), PVC (21%) Acrylic (16%) and Wood (14%).

Stephen Davis, EMEA Marketing Director at Roland DG comments: “We conducted this study to understand how UV is changing the landscape and opening up a new group of materials for printing and personalisation. The data suggests that businesses embracing UV technology as part of their overall product offering are expecting a steady increase in commercial opportunities as a result.”

The research also revealed a healthy demand for a number of other more unorthodox materials, with a quarter (28%) of those polled printing on Glass at least once a month, in addition to Faux Leather or Leatherette (24%), Ceramics (17%) and Slate (15%). Some of the most unusual items that UV printers reported using included a pair of wooden maracas, a wax thermometer, an aluminium radiator, a lute and a glass thermometer.

Davis continues: “UV printing is enabling businesses everywhere to leverage a diverse range of materials, including weird and wonderful items. Making an investment in a UV printer opens up a new world of potential possibilities for your customers and opportunities for you and your team to experiment and innovate.”

However, the evidence also shows that other materials are still used only rarely despite the dexterity of UV printing. The least used material according to the study was Concrete with just 1% using it on a monthly basis. Cork and Silicone were also less popular with just 6% using it for a job each month.

Wild Distillery, a micro distillery that produces organic gin and vodka on the Danish island of Bornholm, is using a Roland VersaUV LEC2 S-Series to create bespoke direct-to-glass bottle designs for a range of major food and beverage manufacturers. Its owner, Henrik Nerst comments: “Owning an in-house printer has allowed me to be more flexible with my offerings, and single-handedly enabled me to branch into the personalisation market. I am incredibly proud of the bespoke designs we have been able to create.”

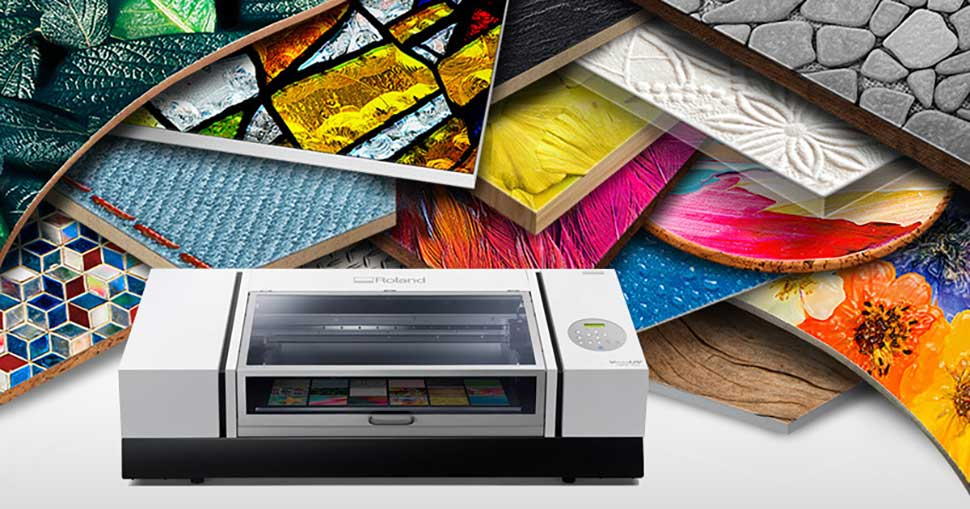

Roland’s VersaUV LEC2 S-Series enables users to print onto a virtually limitless range of flexible and rigid substrates and objects, offering a printable height of 200mm and weight capacity on the printing table of 100kg/m². It delivers a fast turnaround on jobs, with prints instantly ready for finishing and installation.

For more information, contact your Roland authorised dealer.