Mimaki

-

Sign & Digital UK launches new Digital Signage Theatre

15 Apr 2016

Sign & Digital UK, the country’s leading trade show for the sign, display and print industry, today announces the launch of a new Digital Signage Theatre ahead of its 2016 show.

-

YPS reveals partners to present textile workflow at SDUK

14 Apr 2016

Your Print Specialists is set to bring new partners to Sign and Digital UK, providing complementary solutions for its ‘three routes to profitability’ initiative.

-

Top product launches at Sign & Digital UK 2016

13 Apr 2016

Sign and Digital UK 2016 is shaping up to be as popular as ever, with over 7,000 visitors expected through the doors to discover some of the industry’s latest technology.

-

QPS makes last-minute addition to SDUK with Nazdar ink debut

13 Apr 2016

Quality Print Services have added yet another brand new digital ink to its line-up for Sign and Digital UK: Nazdar LWU705 Series UV ink formulated specifically for HP FB500/700 printers.

-

SDUK announces latest exhibitor news ahead of 2016 show

12 Apr 2016

Sign & Digital UK, the country’s leading trade exhibition for the sign making, display solutions and digital printing industry, takes place at the NEC Birmingham, 19-21 April 2016.

-

SDUK announces latest exhibitor news ahead of 2016 show

12 Apr 2016

Sign & Digital UK, the country’s leading trade exhibition for the sign making, display solutions and digital printing industry, takes place at the NEC Birmingham, 19-21 April 2016.

-

Zünd S3 cutter opens up new business opportunities for Nene Packaging

12 Apr 2016

Nene Packaging has installed a Zünd S3 digital cutting table at its Northampton factory, enabling it to produce packaging and display samples for customers of all sizes.

-

New Roland VersaUV LEJ-640FT printer takes creativity to new heights

12 Apr 2016

Roland DG (UK) is pleased to announce the launch of the VersaUV LEJ-640FT, the newest in the series of popular UV ink-based printers.

-

Demo a Mimaki at SDUK and enter holiday prize draw event

12 Apr 2016

To celebrate its 20th year in business, Hybrid - Mimaki’s exclusive UK and Irish distributor - has announced a fantastic free competition for the forthcoming Sign & Digital UK exhibition. Visitors who partake in a Mimaki printer demonstration with one of the company’s authorised resellers during the show will receive a ‘Sporting Ticket’ that could win them a holiday at Club La Manga in southern Spain, worth up to £5,000.

“With a big summer of sport ahead of us, we thought our competition was a great way to get people in the mood,” says Hybrid director; Peter Mitchell. “It was a privilege to experience Mimaki celebrating its 40th year in 2015 and we’re enormously proud that Hybrid is turning 20 years old in 2016. Sign & Digital UK is the perfect occasion to kick things off with a prize like this.”

Hybrid’s Sporting Tickets not only enter visitors into the competition, but also ensure their involvement in the company’s promotions for the show. “We will have some extremely attractive offers on Mimaki’s latest technology during the show,” confirms Mitchell. “The exhibition is an excellent opportunity for companies to explore our printers and benefit from competitive pricing too.”

Hybrid is using the exhibition to not only celebrate its 20th birthday, but to launch two important new printers for Mimaki – the much-anticipated 3.2m LED UV UJV55-320 roll fed machine that saw its European launch in March and the mid format UJF-7151plus flatbed that offers a unique combination of ultra-high quality and productivity. The company will also show the MTEX Blue all in one dye sublimation printer with inbuilt fixation for the first time, along with core sign and graphics solvent printers and integrated printer/cutters.

“We look forward to welcoming partners old and new to the Hybrid stand during the show,” concludes Mitchell. “In our 20th year, we’re as excited as ever about Mimaki’s technology and the opportunity to show all the latest solutions for the sign and graphics market. Our prize draw should be the icing on the cake for what’s set to be a great exhibition.”

Hybrid can be found on stand E10.

-

Demo a Mimaki at SDUK and enter holiday prize draw event

12 Apr 2016

To celebrate its 20th year in business, Hybrid - Mimaki’s exclusive UK and Irish distributor - has announced a fantastic free competition for the forthcoming Sign & Digital UK exhibition. Visitors who partake in a Mimaki printer demonstration with one of the company’s authorised resellers during the show will receive a ‘Sporting Ticket’ that could win them a holiday at Club La Manga in southern Spain, worth up to £5,000.

“With a big summer of sport ahead of us, we thought our competition was a great way to get people in the mood,” says Hybrid director; Peter Mitchell. “It was a privilege to experience Mimaki celebrating its 40th year in 2015 and we’re enormously proud that Hybrid is turning 20 years old in 2016. Sign & Digital UK is the perfect occasion to kick things off with a prize like this.”

Hybrid’s Sporting Tickets not only enter visitors into the competition, but also ensure their involvement in the company’s promotions for the show. “We will have some extremely attractive offers on Mimaki’s latest technology during the show,” confirms Mitchell. “The exhibition is an excellent opportunity for companies to explore our printers and benefit from competitive pricing too.”

Hybrid is using the exhibition to not only celebrate its 20th birthday, but to launch two important new printers for Mimaki – the much-anticipated 3.2m LED UV UJV55-320 roll fed machine that saw its European launch in March and the mid format UJF-7151plus flatbed that offers a unique combination of ultra-high quality and productivity. The company will also show the MTEX Blue all in one dye sublimation printer with inbuilt fixation for the first time, along with core sign and graphics solvent printers and integrated printer/cutters.

“We look forward to welcoming partners old and new to the Hybrid stand during the show,” concludes Mitchell. “In our 20th year, we’re as excited as ever about Mimaki’s technology and the opportunity to show all the latest solutions for the sign and graphics market. Our prize draw should be the icing on the cake for what’s set to be a great exhibition.”

Hybrid can be found on stand E10.

-

SDUK visitors offered chance to win luxury stay in Bruges, courtesy of Colourgen & Mutoh

11 Apr 2016

Visitors to Sign and Digital UK 2016 can win a luxury night’s stay in a 5-star hotel in Bruges with £250 travel/spending allowance from Colourgen and Mutoh.

-

SAi announces free update for FlexiPRINT HP Latex Edition software

11 Apr 2016

SA International (SAi) has announced the release of a free Version 12 download for all existing licenses of the SAi FlexiPRINT HP Latex Edition software.

-

CSL to host Lightbar demonstrations on Roland stand at SDUK

11 Apr 2016

Lightbar roll to roll UV print technology will be demonstrated on the Roland DG stand at Sign and Digital UK once again this year.

-

Roland users to attend SDUK 2016 and inspire potential customers

10 Apr 2016

Roland DG will be joined on their stand (H30) by several users who will share experiences of working with Roland technology to broaden their business offering or deliver demanding requirements.

-

ITE to demo power of in-house digital label printing at Food & Drink Expo

8 Apr 2016

Impression Technology Europe (ITE) will be demonstrating the power of in-house digital label printing at the at the Food & Drink Expo show at NEC Birmingham.

-

Consistency, price & support win Nazdar & QPS customer loyalty

5 Apr 2016

Marshall Signs, one of the first UK-based print businesses to try Nazdar 702 series UV inkjet inks, remains a very satisfied customer a number of months on.

-

Drytac to showcase exciting new products on Antalis’s stand at SDUK

5 Apr 2016

Drytac Europe, an international manufacturer of self-adhesive materials for the print, label and industrial markets, has announced its plans for Sign & Digital UK 2016.

-

SMGG returns to Sign & Digital UK with a PageWide focus

4 Apr 2016

Stanford Marsh Group Graphics, the commercial graphics division of Stanford Marsh Group, will be focusing on the latest HP PageWide printers at Sign & Digital UK.

-

i-Sub to host UK debut of four new solutions at SDUK 2016

4 Apr 2016

Print specialist i-Sub will be presenting a range of wide-format print, packaging, textile and finishing technology on Stand F10 at Sign & Digital UK 2016.

-

i-Sub to host UK debut of four new solutions at SDUK 2016

4 Apr 2016

Print specialist i-Sub will be presenting a range of wide-format print, packaging, textile and finishing technology on Stand F10 at Sign & Digital UK 2016.

-

What’s a Bottle without a title? Glass printing with UV

4 Apr 2016

In his latest blog, Mike Horsten, General Marketing Manager EMEA at Mimaki Europe B.V., discusses the value of printing glass:

The world of cosmetics is the place to show off, often with fancy printed bottles and glass containers whose value is higher than the contents inside.

Yes, the container has been more important to this industry than any other. With a good-looking bottle, you can sell more; with a good fragrance in an ugly bottle, the sales are likely to be low and unprofitable.

This presents a great opportunity for digital print. Today, the cosmetics industry is facing the challenge of what I call the “Personal Luxury feeling.” The ability to buy your own personalised cosmetics or perfume containers will be a big trend in the not-too-distant future. Just imagine a standard bottle with the print different for each customer! It is a new sales and marketing strategy that will change the cosmetics industry. It would drive profits up, since many consumers would pay extra for this service.

But there are some problems, of course, or perhaps it would already be a widespread practice. Glass printing is not easy; the print needs to be able to withstand alcohol and rubbing tests, the print needs to be human safe, and it needs to be very clear and sharp. The reason for the clarity and sharpness is the large amount of fine text that is needed on a cosmetics product, including the ingredients, shelf life and the barcode for the product; they all need to be sharp and straight. Printing on a flat surface is easy; but most bottles are round, so there needs to be a simple way to print on round objects. Some products are in big containers and some are in small round ones, like mascara or liquid foundation. So there are some hurdles to overcome. In addition, many of the caps for these products are made of plastic, which presents yet another challenge.

Traditionally, printing on glass was done via tampon/pad silkscreen printing. This process requires a new print for each colour, which is why you see so many cosmetics products with only one colour print, mostly white. Using more colours is difficult due to the fact that you need to line up the different colours and you would have to use halftone screens to get the job done. I’m not even speaking of the registration problems one would face between colours. On a round object, this would be a real nightmare. Then you need to know that the current generation of primer and/or inks that are used have been specially made for glass printing, specifically for good adhesion to the glass object. Another problem is that the glass is moved through the filling machines after it has been printed, so there is always a risk that the print will be scratched or damaged, making the container unsellable. To address this risk, most printers put a large amount of ink on the container to make sure it stays on. This can be seen on most cosmetics products on the shelf today.

With a digital printing system, we can eliminate most of these problems. First, we can print in 16.8 million colours in contone mode, giving us nice photographic quality. We can add a varnish layer for protection of the print, and we can make each bottle personal. We can print them on demand, so no big production runs would be needed, saving huge amounts in inventory costs and improving cash flow. For printing on flat surface bottles and containers, this is already being done today, used by many of the larger brands for their specials and personalised holiday gifts, using products like our UJF Series printers. We have printed cosmetics boxes and containers around the holiday times in places like department stores such as Harrods in London, and in many airports around the world. Live printing, just wait 10 minutes and your personal product is ready. But this has always been a promo print, a “now or never” type of deal, and it certainly is not a common practice today. Although it has been very successful, it does not solve the production problems for small batches that need to be printed around the world. Did you know that there are more than 50 standards for the labelling of cosmetics products in the world? The languages, the legislation and the fine print are different from jurisdiction to jurisdiction. Customising the packaging translates to unsustainable costs for high-street brands whose expensive perfumes and cosmetics might be produced in low volumes with diverse content.

We have been working on a solution for these problems together with the primary players using the new generation of UV-LED curing flatbed Mimaki printers. We have developed new inks and printable primers that can be used to print on glass. Although there are always some extra requirements needed for printing directly on glass, we have solutions like external primers that help minimise those challenges. The biggest challenge, though, was printing on round objects. This has never been easy, but with the addition of our optional Kebab solution, we are now able to print on round objects with a diameter ranging from 1 cm to 11 cm. This means you can print just about all types of bottles and containers with one printer. The examples are numerous and the applications endless. The funny thing is that you can even print customised content on the boxes containing your special product. Our UJF7151 Plus was made for an industrial market that demands high-speed production and quality all at the same time.

Working on the development of new and faster printers for the industrial glass print markets has brought some challenges to the marketplace, but we have a viable, affordable solution available today that will help to begin this exciting packaging transformation.

So next time you look at a cosmetics or perfume bottle, think about how it would look without print. Or better yet, visualise it customised especially for you with text or images of your choosing. As I said, “What’s a bottle without a title?”

Let’s Create Together

Mike Horsten, General Manager Marketing EMEA @ Mimaki Europe

-

What’s a Bottle without a title? Glass printing with UV

4 Apr 2016

In his latest blog, Mike Horsten, General Marketing Manager EMEA at Mimaki Europe B.V., discusses the value of printing glass:

The world of cosmetics is the place to show off, often with fancy printed bottles and glass containers whose value is higher than the contents inside.

Yes, the container has been more important to this industry than any other. With a good-looking bottle, you can sell more; with a good fragrance in an ugly bottle, the sales are likely to be low and unprofitable.

This presents a great opportunity for digital print. Today, the cosmetics industry is facing the challenge of what I call the “Personal Luxury feeling.” The ability to buy your own personalised cosmetics or perfume containers will be a big trend in the not-too-distant future. Just imagine a standard bottle with the print different for each customer! It is a new sales and marketing strategy that will change the cosmetics industry. It would drive profits up, since many consumers would pay extra for this service.

But there are some problems, of course, or perhaps it would already be a widespread practice. Glass printing is not easy; the print needs to be able to withstand alcohol and rubbing tests, the print needs to be human safe, and it needs to be very clear and sharp. The reason for the clarity and sharpness is the large amount of fine text that is needed on a cosmetics product, including the ingredients, shelf life and the barcode for the product; they all need to be sharp and straight. Printing on a flat surface is easy; but most bottles are round, so there needs to be a simple way to print on round objects. Some products are in big containers and some are in small round ones, like mascara or liquid foundation. So there are some hurdles to overcome. In addition, many of the caps for these products are made of plastic, which presents yet another challenge.

Traditionally, printing on glass was done via tampon/pad silkscreen printing. This process requires a new print for each colour, which is why you see so many cosmetics products with only one colour print, mostly white. Using more colours is difficult due to the fact that you need to line up the different colours and you would have to use halftone screens to get the job done. I’m not even speaking of the registration problems one would face between colours. On a round object, this would be a real nightmare. Then you need to know that the current generation of primer and/or inks that are used have been specially made for glass printing, specifically for good adhesion to the glass object. Another problem is that the glass is moved through the filling machines after it has been printed, so there is always a risk that the print will be scratched or damaged, making the container unsellable. To address this risk, most printers put a large amount of ink on the container to make sure it stays on. This can be seen on most cosmetics products on the shelf today.

With a digital printing system, we can eliminate most of these problems. First, we can print in 16.8 million colours in contone mode, giving us nice photographic quality. We can add a varnish layer for protection of the print, and we can make each bottle personal. We can print them on demand, so no big production runs would be needed, saving huge amounts in inventory costs and improving cash flow. For printing on flat surface bottles and containers, this is already being done today, used by many of the larger brands for their specials and personalised holiday gifts, using products like our UJF Series printers. We have printed cosmetics boxes and containers around the holiday times in places like department stores such as Harrods in London, and in many airports around the world. Live printing, just wait 10 minutes and your personal product is ready. But this has always been a promo print, a “now or never” type of deal, and it certainly is not a common practice today. Although it has been very successful, it does not solve the production problems for small batches that need to be printed around the world. Did you know that there are more than 50 standards for the labelling of cosmetics products in the world? The languages, the legislation and the fine print are different from jurisdiction to jurisdiction. Customising the packaging translates to unsustainable costs for high-street brands whose expensive perfumes and cosmetics might be produced in low volumes with diverse content.

We have been working on a solution for these problems together with the primary players using the new generation of UV-LED curing flatbed Mimaki printers. We have developed new inks and printable primers that can be used to print on glass. Although there are always some extra requirements needed for printing directly on glass, we have solutions like external primers that help minimise those challenges. The biggest challenge, though, was printing on round objects. This has never been easy, but with the addition of our optional Kebab solution, we are now able to print on round objects with a diameter ranging from 1 cm to 11 cm. This means you can print just about all types of bottles and containers with one printer. The examples are numerous and the applications endless. The funny thing is that you can even print customised content on the boxes containing your special product. Our UJF7151 Plus was made for an industrial market that demands high-speed production and quality all at the same time.

Working on the development of new and faster printers for the industrial glass print markets has brought some challenges to the marketplace, but we have a viable, affordable solution available today that will help to begin this exciting packaging transformation.

So next time you look at a cosmetics or perfume bottle, think about how it would look without print. Or better yet, visualise it customised especially for you with text or images of your choosing. As I said, “What’s a bottle without a title?”

Let’s Create Together

Mike Horsten, General Manager Marketing EMEA @ Mimaki Europe

-

MTEX to celebrate a year of growth and innovation at SDUK

3 Apr 2016

MTEX will be celebrating a year of outstanding growth and innovation at Sign & Digital UK 2016 by showcasing the high speed version of its MTEX 5032 printer.

-

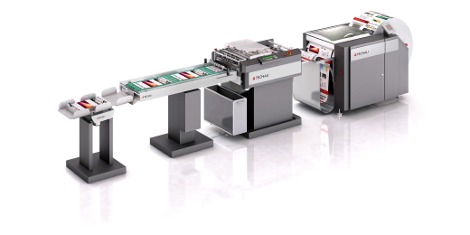

Tecnau to exhibit CutReady at upcoming events

30 Mar 2016

Tecnau’s CutReady solution will showcase its ability to cut and stack output from HP Indigo Digital Presses during several HP Indigo events in Israel, and then at drupa.

-

Nazdar SourceOne adds two inside sales representatives

30 Mar 2016

USA-based Nazdar SourceOne is pleased to announce the addition of Sam Evans and Jordyn Ruhnke to the Nazdar SourceOne Inside Sales team.

-

Roland DG named by InfoTrends as leading seller of wide-format durable graphics printers in 2015

29 Mar 2016

Roland DG was again recognised as the leading wide-format printer manufacturer in the durable graphics market for 2015 in a recent report by InfoTrends.

-

Roland DG announces plans for SDUK 2016

23 Mar 2016

Roland DG has announced it will be hosting a wide range of informative presentations at this year’s premier print and signage show, Sign & Digital UK 2016.

-

Sign & Digital UK announces new vehicle wrap workshop

23 Mar 2016

Sign & Digital UK, the country’s leading trade exhibition for the sign, display and print industry, today announces the full programme for its new 'become a wrap expert' workshop.

-

Life’s a beach for Neschen and ArtSystems at SDUK 2016

23 Mar 2016

Visitors to this year’s Sign & Digital UK should be sure to bring a bucket and spade with them – and a sweet tooth.

-

Lewis & Wood invest in direct-to-textile MTEX Blue Printer

22 Mar 2016

Textile and wallpaper specialist Lewis and Wood are the first UK company to take delivery of the MTEX Blue with Pigments inks.

-

Roland DG's True VIS VG Series captures the imagination at FESPA

22 Mar 2016

Roland DG enjoyed a highly successful FESPA Digital with the global launch of its latest generation of integrated print and cut devices - the TrueVIS VG Series.

-

HEXIS to showcase latest solutions at Sign & Digital UK 2016

15 Mar 2016

HEXIS UK will be showcasing a wide range of new products from its four key divisions – sign, digital, automotive and textile - at Sign & Digital UK 2016.

-

Nazdar appoints Altair Servis MMC as distributor in Azerbaijan

15 Mar 2016

Nazdar Ink Technologies has announced the appointment of Altair Servis MMC as a distributor of its digital ink solutions in Azerbaijan.

-

Canon Océ Arizona 1200 series to make UK debut at SDUK 2016

14 Mar 2016

Canon will present the Océ Arizona 1280 GT flatbed printer to the UK for the first time at Sign & Digital 2016.

-

2016 World Wrap Master Champion announced in Amsterdam

13 Mar 2016

Jim Miller, owner of Millers Decals, USA, has won the prestigious title of World Wrap Master at FESPA Digital 2016.

Sponsored by Avery Dennison and Mimaki, the European leg of the competition, which took place over the first two days of the show attracted 28 competitors from 15 countries and saw Jim named European Wrap Master. He then joined those who had already taken part in Wrap Masters’ events globally for the World Series ‘final battle’ over 10-11 March.

Ruan Greeff, South Africa (Wrap Master Africa 2015) and Michael Szwacki, UK, took second and third place, winning prize money of €1,250 and €750 respectively, as well as gift bags. Jim has received €2,500 but more importantly the global recognition and invaluable networking opportunities that taking part in this competition brings.

Wrapping a variety of items, including Audi A1 Sportbacks, clogs and superhero items, the entrants were judged by expert wrappers and trainers; Ole Solskin, Justin Pate, Kiss Lajos (winner 2014/2015) and John Duever.

Duncan MacOwan, Head of Events, FESPA, comments: “This year has been a nail-biting, edge of your seat competition as the calibre of entrants has been so high. There could, however, be only one Wrap Superhero, and Jim’s technical abilities shone through. It’s also been great to see non-competitors learn more about wrapping through the daily workshop sessions, as it’s such a rapidly expanding market offering a host of new opportunities that PSPs can begin to offer their clients.”

[Picture caption - from left to right: Michael Szwacki (UK – third place), Jim Miller (USA – winner), Ruan Greeff (South Africa – second place)]

-

2016 World Wrap Master Champion announced in Amsterdam

13 Mar 2016

Jim Miller, owner of Millers Decals, USA, has won the prestigious title of World Wrap Master at FESPA Digital 2016.

Sponsored by Avery Dennison and Mimaki, the European leg of the competition, which took place over the first two days of the show attracted 28 competitors from 15 countries and saw Jim named European Wrap Master. He then joined those who had already taken part in Wrap Masters’ events globally for the World Series ‘final battle’ over 10-11 March.

Ruan Greeff, South Africa (Wrap Master Africa 2015) and Michael Szwacki, UK, took second and third place, winning prize money of €1,250 and €750 respectively, as well as gift bags. Jim has received €2,500 but more importantly the global recognition and invaluable networking opportunities that taking part in this competition brings.

Wrapping a variety of items, including Audi A1 Sportbacks, clogs and superhero items, the entrants were judged by expert wrappers and trainers; Ole Solskin, Justin Pate, Kiss Lajos (winner 2014/2015) and John Duever.

Duncan MacOwan, Head of Events, FESPA, comments: “This year has been a nail-biting, edge of your seat competition as the calibre of entrants has been so high. There could, however, be only one Wrap Superhero, and Jim’s technical abilities shone through. It’s also been great to see non-competitors learn more about wrapping through the daily workshop sessions, as it’s such a rapidly expanding market offering a host of new opportunities that PSPs can begin to offer their clients.”

[Picture caption - from left to right: Michael Szwacki (UK – third place), Jim Miller (USA – winner), Ruan Greeff (South Africa – second place)]

-

Students show diverse range of work created in collaboration with Epson technology

12 Mar 2016

The RA Schools Premiums Interim Projects exhibition took place for the first time in the historic Sackler Wing of Galleries at the Royal Academy. The annual show provides a unique opportunity to view exciting new work by 17 emerging and international artists at the interim point of their postgraduate study at the UK’s longest established art school, the RA Schools. Many of the works on display were produced using Epson technology and media, which are all accessible onsite to the students within the Schools’ Epson-sponsored Digital Media Suite.

Providing the Schools with state-of-the-art large format digital printing, AV projection technologies and specialist media, gives students the opportunity to experiment with a wide range of work incorporating a wide range of practices, from hand-made objects and wallpaper installations to paintings and trompe l’oeil, as well as film, woodcuts, photography, film and sound.

The only free three-year postgraduate course in the UK, the RA Schools programme is tailor-made to the individual student, affording each artist the space and flexibility to develop work across a broad array of media. Epson has been an integral part of the Schools fabric for several years, offering support and guidance to the students and staff, and the freedom to experiment and engage with technologies to produce a diverse range of work.

There was much evidence this year of the creative collaboration between students and Epson technologies, with all of the students having utilised the Epson Digital Media Suite at some point during their study.

This was particularly evident in the works of five of the artists on show:

- Jack Burton works with high-gloss colour photographic prints of complex still life, often constructed from sculptural collages of found objects, customized spaces and earlier produced photographic images, printed using an Epson large-format printer.

- India Mackie produces large scale video installations using Epson HD projectors to create physical 4D experiences in high resolution.

- Martin Gross creates prints that span centuries of print processes on their journey of production. He begins by making drawings that are scanned, these become rasterised translations that then become wood-cut stencils via laser cutting equipment and digital print. These manifest as large format digital wallpaper installations that can be customised to fill and match bespoke environments and additionally they can become smaller framed-sized editions that utilise both state-of-the-art Epson inkjet printing and traditional 18th century wood engraving.

- Dimitri Gallitzine produces work across a broad range of media. For Premiums, he created and projected a ‘mockumentary’ film, using an Epson HD projector, in which he documented a journey where he attempted to become a professional Elvis impersonator.

- Sebastian Jefford is a sculptor of idiosyncratic objects made from a combination of diverse materials that include nails, wood, Plasticine, drawing and printing. The material skins which surround them are printed with screen printed Plasticine from film positives produced on a large format Epson printer. Jefford triumphs by an almost miss-use of the technologies intended functions.

Mark Hampson, Head of Fine Art Processes at the RA Schools, who along with his specialist team is responsible for facilitating the students creative ambitions in the RA workshops, says of this group of students: "Our students never cease to surprise me in their creativity and the manifestations of their uses and abuses of the technology and equipment we are able to offer them at the RA Schools. They constantly surprise with their use of the available resources and the ambition with which they can apply these in their Art. This year’s Premiums is an amazing example of the strength of our collaborative project with Epson. Without Epson's support and the sponsorship of equipment and its technical knowledge, many of these artworks would not have been conceivable.

Epson offers us the means and conceptual virtuosity to think laterally about technology and the implications and effects of our digital age. They do this with wonderful generosity and complete trust, often knowing that the resulting artistic consequences may be bizarre, unexpected, un-commercial but always exciting. I cannot think of a more positive way for industry and art education to collaborate and support each other."

Further information on the RA Schools and upcoming events: www.royalacademy.org.uk/page/the-ra-schools

[Image by Andy Keate.]

-

Mimaki UJV55-320 grand-format printer makes European debut at FESPA

9 Mar 2016

Mimaki has announced the introduction of a brand-new 3.2m roll-to-roll inkjet printer.

-

Mimaki UJV55-320 grand-format printer makes European debut at FESPA

9 Mar 2016

Mimaki has announced the introduction of a brand-new 3.2m roll-to-roll inkjet printer.

-

HP reinvents mid-volume industrial category for print providers

7 Mar 2016

HP Inc. today introduced the HP Scitex 9000 Industrial Press and HP HDR245 Scitex Inks, enabling industrial production speeds at an entry-level investment.

-

QPS to showcase host of new Nazdar inks at Sign and Digital UK 2016

7 Mar 2016

Quality Print Services (QPS) has announced its full line-up for Sign and Digital UK (April 19th to 21st 2016) with a range of brand new Nazdar inks on show.

As part of QPS's largest ever Sign and Digital UK stand (72sqm, stand number L10), new Nazdar 130 Series inks will run on a Mimaki JV300 wide-format ink-jet solvent printer. Promoted for the first time at FESPA Digital 2016 this March, British audiences will be able to see the

exceptional compatibility and quality of Nazdar 130 Series inks just a few weeks later.QPS will also demonstrate another new Nazdar formulation for the wide-format sector, the new Nazdar 203 Series inks, which are designed as a colour-matched, plug-and-play alternative to Roland Eco Max 3 inks.

An HP L26500 Latex printer will also be running on QPS's super-sized stand, demonstrating the new Nazdar 285 Series, matched to HP 792 series OEM ink.

Furthermore, QPS will present a taste of its range of energy-efficient and robust LED UV printers from Longier. The Longier Hunter FR3750 offers low-energy yet high-quality printing at speeds of up to 70sqm/hr, while its 2x8 print-head configuration enables printing with process colours, white and varnish. The Hunter FR3750 will also be running Nazdar high-quality digital inks.

"We anticipated a flurry of new Nazdar ink releases this spring and booked our biggest ever Sign and Digital UK 2016 stand – 72sqm – with the intention of showing as many as possible," says Chris Bailey, Managing Director of QPS. "Nazdar digital inks are known for their cost effectiveness and our customers report saving significant sums on consumables costs each month. But we will also be demonstrating their quality, colour vibrancy, adhesion and durability on both market-leading printer systems and on our excellent Longier flatbed printer range."

QPS is also pleased to announce that it has been appointed as a reseller for Vivid Technologies, meaning it now supplies the full Easymount range of wide-format film laminators. QPS representatives will be on hand at Sign and Digital UK to give attendees information on the whole Easymount range, from entry-level models to heavy-duty thermal systems designed for 24-7 operation.

QPS will exhibit on stand L10 at Sign and Digital UK 2016. To book a meeting or for more information about QPS's large-format print products and services, please email sales@qualityprintservices.com or call 01704 897575.

For more information on Nazdar and its comprehensive range of ink solutions, please visit www.nazdar.com.

-

Epson Control Dashboard: management solution for SC-S printers

6 Mar 2016

Following the recent launch of the SureColor SC-S Series of wide-format inkjet printers, Epson announces the introduction of Epson Control Dashboard.

-

HP honoured with 2016 iF Gold “Best of Best” Design Award

5 Mar 2016

HP Inc. today announced that the HP PageWide XL 8000 Printer has been honoured with the prestigious 2016 iF Gold “Best of Best” Design Award.

-

Mimaki getting creative for close-up at Cosmopack and SDUK

5 Mar 2016

Mimaki will showcase innovative packaging ideas for the cosmetics industry at Cosmopack in Italy and general packaging and promotional items at Sign & Digital UK.

-

Mimaki getting creative for close-up at Cosmopack and SDUK

5 Mar 2016

Mimaki will showcase innovative packaging ideas for the cosmetics industry at Cosmopack in Italy and general packaging and promotional items at Sign & Digital UK.

-

Antalis launches comprehensive guide to Sign & Display products

2 Mar 2016

Antalis UK has launched a new 108-page guide to its full range of sign and display products, featuring many new products. In a market that is constantly evolving, the guide - which is aimed to help customers in the selection of substrates for different applications - includes every product offering from PVC, large format papers and finishing products. In addition, it presents visual representations of the possible applications for each substrate, helping printers identify how each product can be printed to obtain the best results, along with fire and slip ratings making it easier than ever to select the right product.

The guide includes Antalis's full and extensive range, including familiar brands such as 3A, Drytac, Priplak and Orafol; the pan-European Coala range of large format digital media; and an exciting range of wall-coverings from Graham & Brown, showcasing a variety of creative embossings and finishes. Recently launched and also included in the guide is Dispa board – 3A’s new 100% recyclable FSC board with a unique embossed core, making it rigid, sturdy and flat.

Commenting on the launch of the guide, Mike Collins, Sign & Display Product Manager says: “In a market where more and more printers are diversifying their capabilities and branching out in to large format production, this guide will be invaluable to those looking for help in selecting the best product for their applications.”

Mike continues: “We have worked hard to build a strong portfolio of sign and display products so customers can source everything they need, quickly and efficiently from one supplier.”

A hard copy of the Guide can also be obtained by contacting the local Antalis sales office or by calling 0370 607 9014.

-

Drytac announces ViziPrint Illuminate for backlit graphics

2 Mar 2016

Drytac Europe, an international manufacturer of self-adhesive materials for the print, label and industrial markets, has announced ViziPrint Illuminate.

-

ArtSystems announces arrival of Xativa 3D Filament to UK market

2 Mar 2016

Nottingham-based specialist distributor, Artsystems, has announced the arrival of Xativa’s cost-effective and high quality 3D Filament to the UK market.

-

HEXIS UK adds new eco-friendly films to its portfolio

1 Mar 2016

HEXIS UK Ltd. has announced new PVC-free eco-friendly films for digital printing and signage applications.

-

Print On Cheadle moves up a gear with new premises and Mimaki kit

1 Mar 2016

Cheshire-based printers, Print On, has really graduated to a different league in recent months with a move to impressive new 6,000 sq. ft. premises on Lawnhurst Industrial Park in Cheadle. The company’s future ambitions are evident as you walk through the front door past a well-appointed boardroom and customer meeting room, to be faced with a large modern reception area, beyond which stretches a very impressive open-plan print hall.

The first thing that strikes you is the tidiness of the whole place – open plan work areas can certainly expose a company’s weaknesses to visitors, but not here; Print On is more than happy to lay its soul bare and proud to let its customers see exactly how the company operates.

With a core staff of just 8 people, it’s obvious that efficiency is the name of the game, with each member of the team having clear focus and direction and being more than capable of multi-tasking, including the family directors of the business, who are remarkably hands-on. As Managing Director, Alex Oldfield explains, “We’re a tight-knit family business. I get amazing support from my father and mother in their respective roles of Marketing Director and Financial Director and none of us shy away from getting our hands dirty – we take real pride in what we do and get involved on a daily basis in every aspect of the operation.”

The impressive premises suggest that the business is prospering in what many still consider to be a challenging economy, so how has Print On managed to develop so successfully? Alex’s father Keith is confident in his response: “We’ve always believed our two key assets to be our staff and the equipment we use and there’s been no shortage of investment in either.”

Print On has traditionally based much of its production capability around its impressive arsenal of four Xerox Versant digital printers, but became increasingly aware that the ability to offer a more diverse range of print services would be crucial to retaining existing customers and also developing new revenue streams. As Alex explains: “Some of our larger retail customers with whom we have really close relationships were placing their PoS or other wide format print requirements with other print providers. We really needed to equip ourselves to meet what seemed to be a growing demand in the sector. Investment in a Mimaki JFX200 flatbed and a brace of Mimaki JV300 production solvent printers sourced through our long-standing relationship with Mimaki reseller Granthams of Preston has really enabled us to stretch our legs and start producing a much wider range of products for our customers.”

Alex cites this significant upturn in business as the catalyst for the move to new premises in January of this year. “We spent a couple of months at the end of last year decorating and refitting the premises to meet our specific requirements and this included a dedicated wide-format area in a separate part of the building to house the array of new Mimaki kit.”

The team’s wide-format specialist, Matt Peters can’t speak highly enough of his new charges as his experience of working with them expands. “I’ve previously worked with other wide-format flatbeds which I’d always felt to be perfectly adequate. But the more I use the Mimakis, the more impressed I am with their performance – the print quality and the speed just blows me away! We hardly ever need to use the highest quality setting on the JFX200, as even in fast production mode the quality is really quite exceptional. I’m regularly printing 8’ x 4’ rigid boards with full ink coverage in around 20 minutes, at a highly acceptable print quality.”

As for the JV300s, Matt enthusiastically describes them as “real workhorses and ultra-reliable.” These two machines have obviously been earning their keep at Print On as evidenced by the fact that under the ink cartridge re-cycling scheme operated by Mimaki’s UK and Ireland distributor, Hybrid Services, over 400 empty 440ml solvent ink cartridges have been re-cycled in less than 12 months operation.

There’s a real buzz about the new premises as everyone seems to be focused on maximising the potential of the heady blend of a mighty impressive kit list and a comfortable and spacious working environment. Customers seem equally impressed, with increased levels of business coming from longstanding clients including many major multi store retailers, as well as a number of new high-profile clients.

As a large printed sign in the Press Hall declares: “Impossible is not a fact. It’s an opinion. Impossible is not a declaration. It’s a dare. Impossible is potential. Impossible is Nothing.” … great words from the great Muhammad Ali. Clearly the small and enthusiastic team at Print On is more than up for a challenge with the confidence that new equipment and premises has brought them.

Further information about Print On's services can be found at www.printonuk.com.

Mimaki's full product range can be found via its UK and Irish distributor, Hybrid Services at www.hybridservices.co.uk.

[Photo caption: The Print On team with directors Keith and Alex Oldfield pictured centre]

-

HP inspires print providers to reinvent possibilities at drupa

29 Feb 2016

HP has announced that it will exhibit the industry’s broadest portfolio of digital printing solutions at drupa 2016.

-

Mimaki CJV300 is a winner for Addprint

28 Feb 2016

The recent Irish Print Awards saw Addprint win the Luxury Packaging Printer of the Year award for its cosmetic beauty box project for Bourjois Paris.

-

Soyang to launch new interior décor collection at SDUK 2016

26 Feb 2016

Soyang Europe returns to Sign & Digital UK 2016 to introduce its new collection of interior decoration materials alongside its textile, signage and graphics ranges.

-

Roland DG showcases collaboration to inspire at FESPA 2016

25 Feb 2016

Roland DG announces details of an exciting collaboration with leading surface pattern designer, Rachael Taylor at FESPA, Amsterdam.

-

Hybrid to debut new Mimaki printers at Sign & Digital UK 2016

24 Feb 2016

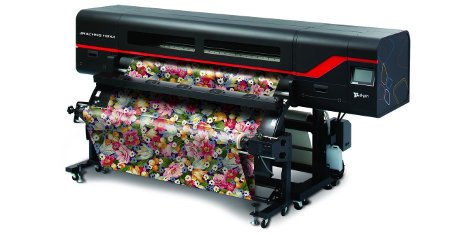

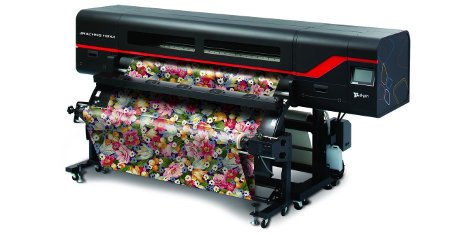

Sign & Digital UK 2016 will see a series of new product launches from exclusive UK and Irish Mimaki distributor, Hybrid Services Ltd, including an LED UV printer making its first outing in the sign and graphics industry. In addition, Hybrid will also be showing the MTEX Blue all-in-one dye sublimation printer on its stand situated at the entrance to the exhibition.

“Visitors to Sign & Digital UK will witness the very newest technology the minute they walk through the door of the show,” says Hybrid’s National Sales Manager for Industrial Products, Stuart Cole. “Our new UJF-7151plus LED UV printer will be one of the first machines they see, so we’re excited to set the tone for what we’re sure will be a fantastic show.”

The Mimaki UJF-7151plus is a mid-format flatbed printer that features exceptionally detailed output coupled with low running costs. With a 710x510mm bed size and industrial construction, consistently high print quality is ensured, making it appealing to screen printers looking for a digital solution that can increase their flexibility as well as quality.

Hybrid is to also show the MTEX Blue dye sublimation printer on its stand for the first time. “The buzz around soft signage and textile printing continues to increase,” says Hybrid’s National Sales Manager for Textile & Apparel, Stephen Woodall. “The MTEX Blue has Mimaki technology at its core and offers a solution that incorporates fixation, enabling users to print and cure dye sublimation ink onto polyester in one process.”

Firmly targeted at the retail PoS, display graphics and exhibition sectors, the new system should see considerable interest at the show, as Woodall concludes: “Companies looking at investing in dedicated textile hardware for the first time will find the ideal solution in the MTEX Blue – it’s easy to use, delivers a vibrant and long lasting print direct to polyester and opens whole new revenue streams for signmakers and print providers.”

Also featuring on the Hybrid stand will be Mimaki solvent printers and printer/cutters, as the company’s National Sales Manager for Sign & Graphics, John de la Roche outlines: “I’m confident we’ll have a solution on the stand for everyone – from start-ups visiting the show for the first time to seasoned professionals. For example, Mimaki’s CJV150 range of printer/cutters is incredibly well priced yet sports features far in advance of even its closest competitor and the range doesn’t stop there!”

Hybrid can be found on stand E10 at the show. Companies wishing to receive more information beforehand can contact the company by visiting www.hybridservices.co.uk.

[Image shows Mimaki UJF-7151plus printer]

-

'Smart' sportswear for Macclesfield Rugby Club, thanks to Mimaki reseller

23 Feb 2016

Macclesfield Rugby Union Club is competing in the 2015/16 season with the benefit of sponsorship from local textile print specialist and Mimaki reseller, R A Smart.

-

'Smart' sportswear for Macclesfield Rugby Club, thanks to Mimaki reseller

23 Feb 2016

Macclesfield Rugby Union Club is competing in the 2015/16 season with the benefit of sponsorship from local textile print specialist and Mimaki reseller, R A Smart.

-

Inspiration & innovation the theme for Antalis at SDUK 2016

22 Feb 2016

Antalis UK is to display and demonstrate its largest ever range of sign and display solutions at Sign & Digital UK, 19-21 April, NEC Birmingham, stand L20.

-

Sabur Digital appointed Mimaki reseller by Hybrid Services.

21 Feb 2016

Supplier of digital textile sublimation equipment and consumables, Sabur Digital has been appointed as a Mimaki reseller by UK and Irish distributor, Hybrid Services.

-

Sabur Digital appointed Mimaki reseller by Hybrid Services.

21 Feb 2016

Supplier of digital textile sublimation equipment and consumables, Sabur Digital has been appointed as a Mimaki reseller by UK and Irish distributor, Hybrid Services.

-

Nazdar to showcase next-generation inks at FESPA Digital 2016

16 Feb 2016

Nazdar Ink Technologies has announced the debut of a number of new inks at FESPA Digital 2016, scheduled to take place at The Amsterdam RAI Exhibition Centre in The Netherlands.

-

Drytac to showcase new products and applications at FESPA 2016

16 Feb 2016

Drytac Europe has announced its plans for FESPA Digital 2016.

-

Roland DG maps out the year ahead with new events website

15 Feb 2016

Roland DG has today launched its Roland DG Roadmap, a new website designed to enable Roland DG users and potential clients to discover upcoming event listings.

-

Mimaki JV300 fits the bill for Dublin-based IQ Group

15 Feb 2016

Dublin-based IQ Group recently added a Mimaki JV300-160 and CG-160FXII to its portfolio of printing hardware through authorised Mimaki reseller, Reprocentre, and the company is 'delighted' with the investment.

The IQ Group is a vibrant company in every sense of the word. From the vivid and high quality print it produces, the positive energy and growth it has experienced since it formed 5 years ago, and even through to the dynamic team and bright and quirky premises, it’s a colourful company. So it’s not surprising that, when they decided to expand their hardware portfolio, the Mimaki JV300-160 solvent printer was befitting of a place in the company's print room.

“Quality is key to IQ,” explains one of the company’s Directors, Gary Upton. “The Mimaki JV300 provides great print quality and continuity of colour every time, regardless of changes in temperature, giving us the ability to colour match perfectly. We’re a reactive company; we offer a fast turnaround for our customers and the JV300 fits right in here giving us speed and flexibility. We’ve been really impressed.”

IQ, or Image Quest as it was formally known, originally started out as a print management service and signage company, but quickly evolved to incorporate in-house print production to make them more cost effective, offer faster turnaround times and give their customers more security and confidentiality. “We offer the complete workflow in-house,” continues Upton. “We have a creative design studio, a highly-productive print department and a team of installation experts, so we can guarantee a premium service and products every time. We do a vast amount of contract work and we need to be consistent on every level, including superior print output, which is exactly what we get with the JV300.”

IQ made the investment in the Mimaki JV300 through authorised Mimaki reseller Reprocentre. Reprocentre's Sales Director Eoin Honan explains: “We’ve provided a variety of hardware and materials for IQ over the last few years, but when they came to us looking for something to increase their productivity without compromising on quality or colour gamut we recommended the Mimaki JV300 solvent printer. It is super-fast and the SS21 solvent inks mean beautiful bright blocks of colour aren’t an issue. We also supplied a Mimaki bulk-ink system (MBIS) with the JV300 which gives IQ higher production levels by running the printer overnight and unattended on long runs.”

Further information about IQ Group is available via its website www.iqgroup.ie.

Further information about Reprocentre and its products and services can be found at www.reprocentre.ie.

Full details of Mimaki’s product portfolio is available via its Irish and UK distributor, Hybrid Services Ltd at www.hybridservices.co.uk.

-

Zünd UK announces availability of Prep Center workflow software

10 Feb 2016

Zünd UK has announced the launch of Prep Center workflow software in the UK, with immediate availability.

-

New Roland printer from QPS ensures festive cheer at Nexvision

10 Feb 2016

Nexvision completes a successful Christmas period after installing a second Roland VersaEXPRESS RF-640 running Nazdar TX-650 dye-sublimation inks, supplied by QPS.

-

i-Sub to show Mimaki UJF-7151plus at Packaging Innovations show

10 Feb 2016

i-Sub Digital announced that it will be showing the new Mimaki UJF-7151plus printer for the first time in the UK at the Packaging Innovations show.

-

HP DesignJet helps New Jersey Search and Rescue save lives

9 Feb 2016

New Jersey Search and Rescue (NJSAR) installed an HP DesignJet T2500 Multifunction Printer (MFP) to produce large-format maps to aid in search-and-rescue missions.

-

Mimaki Vehicle Wrap Lab puts motorsport students in pole position

9 Feb 2016

Hybrid Services Ltd. has teamed up with the UK’s foremost motorsport engineering education establishment, Oxford Brookes University, in a partnership set to take wide format print to a whole new audience. As part of its increasing commitment to supporting young people in print, Hybrid has created the Mimaki Vehicle Wrap Lab, supplying a Mimaki wide format printer, cutting plotter and software package to the University in a relationship intended to provide hands-on experience, expert tuition and a commercial understanding of vehicle wrapping, branding and liveries to undergraduate race engineers set for high profile roles in Formula 1 and other avenues in professional motorsport.

Also involved in the project are material supplier Metamark and expert vehicle wrapper Jason Price, whose employment within the Corbeau Seats group allows him opportunity to provide design, wrapping and installation services for a vast array of clients within the motorsport industry.

“The project is all about making these highly talented engineering undergraduates better aware of some of the commercial requirements within motorsport,” says National Sales Manager for Sign & Graphics at Hybrid, John de la Roche. “However you look at it, motorsport rotates around sponsorship and the importance of getting a professional looking message on and around the cars cannot be underestimated. Mimaki’s range of wide format printing solutions already has a strong presence in vehicle wrapping at all levels – and current F1 teams have been investing in their own Mimaki systems for years but we were keen to provide an opportunity at an early stage of these people’s careers.”

The motorsport engineering students at Oxford Brookes take part in the global Formula Student series of races. These cars mimic scaled down, single seater F1 models – so still boast highly developed aero packages, telemetry systems and cutting edge mechanical engineering.

“It’s the job of the vehicle wrapper to make the car look fast but, additionally, vehicle graphics provide corporate identity making the vehicle look professional,” says Price. “It’s unusual to give this responsibility to the engineers, but in this instance, they’re getting first-hand experience of what’s involved, so it should stay with them throughout their careers.

“There are also sound technical benefits to wrapping a car rather than painting it,” Price continues. “The weight savings are huge so it’s an easy sell on purely technical grounds – let alone the benefits of how the team presents itself.”

Metamark is supplying a range of media to the project along with providing expert advice on additional opportunities for display graphics. “The new MD-X Cylinder cast film is ideal for the students to be using on the cars,” says Samantha Daulton, regional sales manager for Metamark “We’ve also provided our RU500 LayFlat rollup material for use within the Mimaki Vehicle Wrap Lab along with wallpaper and digital frost etched window film.”

Daulton has spent time at Oxford Brookes guiding technicians within the department on best practice with the Metamark product range and Head of Mechanical Engineering and Mathematical Sciences at the University.

Professor Gareth Neighbour, stresses the importance of the mentoring provided by the various partners: “We’re immensely proud of the incredibly high standards of technical tuition on offer to our students, but we’re not afraid to admit that we’re completely new to wide format printing and all that goes with it,” confirms Neighbour. “The extensive training and support from Hybrid and its partners has very swiftly allowed our teaching staff and technicians to get to grips with the technology and offer an exciting new component to our degree and masters courses.”

“We pride ourselves in having the highest percentage of alumni in Formula 1 of all the universities and the development of the Mimaki Vehicle Wrap Lab has added yet another string to our students’ bows, being of great interest at the recent Autosport International show,” says Neighbour.

Oxford Brookes’ impressive facility bears more than a passing resemblance to the HQ of a motorsport team with a vast array of tooling, engineering equipment and testing instruments alongside memorabilia and former race cars and the Mimaki Vehicle Wrap Lab’s central position enables passers-by to see the printing process in operation.

“Bringing vehicle wrapping and branding into the heart of the Technology Centre really helps to remind the students of the importance of how they present themselves and their teams,” concludes Brian Sims – Oxford Brookes MEMS Advisory Board Member, Former Marketing Director of the Benetton F1 Team and Founder and Honorary Life Member of the prestigious Motorsport Industry Association “Having been involved in this project from the outset, I’m delighted to see how the students are already embracing it and using it to their benefit.”

The Mimaki Vehicle Wrap Lab is located at the University’s Wheatley Campus from where Oxford Brookes Racing competes in the global Formula Student series and has over 4,000 followers on its Facebook page. The university offers undergraduate and masters degree courses in motorsport engineering, automotive engineering and motorsport technology along with many others within its Department of Mechanical Engineering and Mathematical Sciences – further information of which can be found by visiting www.mems.brookes.ac.uk.

For all of Mimaki’s latest products and consumables visit UK and Irish distributor, Hybrid Services Ltd’s website www.hybridservices.co.uk.

[Picture captions - Above: Oxford Brookes students wrapping a wing mirror. Below: In the Mimaki Vehicle Wrap Lab (from L to R): Malcolm Evans - Hybrid Services, Dr Neil Fellows - Oxford Brookes University, Prof Gareth Neighbour - Oxford Brookes University, Terrance Floyd - Oxford Brookes University and Jason Price - Corbeau Studio.]

-

Lineker Machines to take Mimaki to Printwear & Promotion LIVE 2016

6 Feb 2016

Lineker Machines is returning to the Printwear & Promotion LIVE exhibition at the NEC from Sunday 28th February to Tuesday 1st March 2016.

-

Canon launches imagePROGRAF iPF770 MFP L36 and iPF670 MFP L24

2 Feb 2016

Canon UK has announced the launch of two new entry-level large format multi-function printers (MFPs).

-

Roland DG’s latest technology to be showcased at New Product Creative Centre Open Day

1 Feb 2016

Roland DG will be holding a New Product Creative Centre Open Day at its HQ in Clevedon on Tuesday 23rd of February 2016 from 8am-4pm.

-

Mimaki set to inspire digital print heroes at FESPA 2016

1 Feb 2016

Mimaki has announced it will have a significant presence at FESPA Digital 2016, scheduled for 8th – 11th March 2016 in Amsterdam.

-

Roland DG to bring the latest technology to SDUK 2016

1 Feb 2016

Roland DG has confirmed that it's set to return as an exhibitor to Sign & Digital UK, which is taking place on 19th - 21st April 2016 at the Birmingham NEC.

-

Canon launches Océ Arizona 1200 Series of UV flatbed printers

26 Jan 2016

Canon Europe has announced the global launch of the Océ Arizona 1200 Series of UV flatbed printers.

-

Epson SureColor SC-S printers to make European debut at FESPA Digital 2016

25 Jan 2016

At Fespa Digital, Epson will show its latest range of SureColor aqueous, solvent and dye-sublimation inkjet printers.

-

New black ink added to Mimaki's range of SB410 sublimation ink spot colours

25 Jan 2016

Mimaki has announced that a light black ink will be added to its range of SB410 sublimation ink spot colours from February 2016. The light black joins the recently released neon yellow and pink fluorescent inks, which are ideal for low-volume, high-quality use in fashion and sportswear and swimwear.

The addition will expand apparel production possibilities for users and will increase the versatility of the TS300P-1800 wide format printer, a dedicated dye sublimation inkjet printer for apparel and textile applications. The new light black inks will be available in two litre ink packs and the TS300P-1800 is scheduled to demonstrate some of the innovative and creative capabilities of the inks at FESPA Digital 2016 in Amsterdam, in Hall 1 on Stand E15 from 8th – 11th March.

“These new spot colours can add real value to fashion and sportswear,” states Stephen Woodall, National Sales Manager for textile and apparel, at Mimaki’s exclusive UK and Irish distributor, Hybrid Services Ltd. “The new light black improves the already high print quality, enhancing photographic images and gradations even further. Alongside the fluorescent pink and yellow inks, users now really have the capability to create highly unique garments.”

Woodall concludes: “The fluorescent samples we have produced on the Mimaki TS300P-1800 are spectacular, so we anticipate that combining this with the new light black will deliver even more eye-catching output. We look forward to demonstrating this to visitors to FESPA Digital in March.”

-

Onyx Graphics rolls out full support for new Epson SureColor SC-S Series printers

25 Jan 2016

Onyx Graphics has announced full support for the recently launched Epson SureColor® SC-S printers, through its proven wide-format print software. The Epson SureColor SC-S Series includes the SC-S80600, SC-S60600 and SC-S40600 models.

According to Epson, this new range of professional 64-inch signage printers combines robust engineering with new design and production features to deliver market-leading quality at the fastest possible speeds, precise repeatability and long-term durability. The new range gives print service providers a choice of printers to suit their specific production needs from 4-10 colours (including white and metallic) and up to 95.3sqm/hr of single-pass productivity.

ONYX software takes full advantage of the SC-S80600 printers’ unique capabilities, including support for 9/10 colour printing, using CMYKLcLmLk plus red and orange inks, as well as full support for white and silver ink configurations.

Specifically developed to make wide-format printing faster, predictable and more affordable, ONYX 12 software – which drives the entire SureColor SC-S Series printer line – enables print operators to print jobs right the first time. ONYX 12 software utilises the power of a next-generation, all 64-bit platform to harness full processing capabilities, delivering not just faster speeds but greater responsiveness as well. This version includes a redesigned user interface for easier navigation making it simple to find, view and edit jobs quickly. With new finishing tools, such as bleed and mark placement combined with full 64-bit processing, ONYX 12 software delivers the printing speed and finishing capabilities needed for the ideal Epson SureColor printing environment.

For more information, please visit www.onyxgfx.com.

-

New Year, new ink: 'sensational' new offer from Roland DG on ECO-SOL MAX inks

24 Jan 2016

Roland DG has announced an exciting special conversion deal to existing Roland DG customers when they upgrade to ECO-SOL MAX 3.

-

Mimaki concludes basic agreement on purchasing stocks of Italy-based La Meccanica Costruzione Tessili-S.P.A

23 Jan 2016

Mimaki Engineering Co., Ltd. announced it has concluded the basic agreement on purchasing stocks of an Italian company La Meccanica Costruzione Tessili-S.P.A. on December 16, 2015.

-

Zünd to showcase modular cutting solutions at FESPA Digital 2016

22 Jan 2016

Zünd Systemtechnik is pleased to present the latest high-performance, ultra-versatile digital cutting solutions at Fespa Digital 2016.

-

Epson’s latest SureColor SC-S wide format ink printers

20 Jan 2016

Large Format Review Editor Derek Pearson recently attended the UK launch of Epson’s new 64-inch SureColor SC-S printers. Here's what he says:

Epson’s new 64-inch SureColor SC-S printers − designed to deliver quality, productivity and durability with lower running costs

Unlike some of its competitors, when you buy Epson what you get is Epson. From the robots that assemble them to the individual components from which they’re made, everything in an Epson printer is of Epson design and manufacture, that was the message made loud and clear at the launch of the latest generation of Epson’s 64-inch wide format printers.

At the prestigious Mercedes AMG Petronas Formula One factory, an exclusive group of journalists were treated to the first viewing of the new SureColor SC-S series, each printer designed to offer users a precise and accurate way to create high impact, durable and profitable signage and display graphics. Easy to use and simple to maintain the new range gives print service providers a choice of printers to suit their specific production needs from 4-10 colours (including white and metallic) and up to 95.3sqm/hr single-pass productivity:

SureColor SC-S80600, the top-of-the-range model features dual PrecisionCore TFP (thin film piezo) printheads and 9/10 colours including CMYKLcLmLk + red and orange, and can also be configured to use white or metallic silver. Operators can easily switch between white and metallic ink to suit job requirements. This flexible printer delivers print speeds up to 95.1sqm/hr in single-pass banner mode, and up to 12.5sqm/hr in 8-pass film mode.

SureColor SC-S60600 is said to be ideal for fast turnaround, high print volume environments featuring dual PrecisionCore TFP printheads (CMYKx2) this printer produces high quality vinyl output at 29.4sqm/hr, banners at 52.3sqm/hr and can print up to 95.3sqm/hr for single-pass applications.

SureColor SC-S40600 has been positioned as a perfect printer for high-quality POS graphics and signage. Affordable with a true entry-level price, this four-colour printer features a single PrecisionCore printhead and delivers up to 58.4sqm/hr productivity.

Everything about the design of the new SureColor SC-S series is centred on improving the printing experience for the user and reducing cost of ownership. Set-up is quick and simple and, once printing is in full flow the large clear panel offers a view of the printing area, while internal LED lights allow for easy inspection at the point of printing.

From outdoor signage to high-end interior displays and décor, the range can create stunning results on a range of coated and uncoated substrates. Exhibition displays, posters and backlit panels, POS materials, vehicle wraps, wallpaper and photo canvases are all produced with a high level of accuracy thanks to the printers’ new Precision Media Feeding System.

This facilitates motorised roll-to-roll media handling with an advanced auto-tension control (AD-ATC) system for extremely accurate media feed and take-up. Anti-static, wide-diameter pressure rollers help optimise grip and feed accuracy, while an innovative media path enables consistent media feed for unattended roll-to-roll printing up to roll weights of 45kg.

Maximum uptime and productivity is further optimised by automatic media alignment and setup which allows fast switching between media types. Automatic printhead cleaning, including a newly-developed fabric printhead wiper system, will virtually eliminate printhead maintenance. A daily maintenance job becomes a fast monthly item or less.

Epson’s latest-generation permanent PrecisionCore TFP printheads with variable size ink droplet technology produce consistent 1440 x 1440 dpi output at ‘best in class’ print speeds. In addition, new hardware enhancements offer greater resistance to head strikes and new Precision Dot screening technology help deliver flawless output on difficult media, including cheap monomeric vinyl, even at fast print speeds.

UltraChrome GS3 inks

The new SureColor SC-S range uses Epson’s new formulation quick drying and low odour UltraChrome GS3 inkset. As well as a substantial reduction in ink price for the new printers, Epson has improved the ink chemistry meaning significantly lower ink consumption resulting in a big improvement in total cost of ownership compared to other printer options on the market.

The new printers allow users to produce a wider colour gamut than ever for highly accurate and repeatable colour reproduction. The top-of-the-range SC-S80600 also benefits from the addition of light cyan & light magenta, red, orange, white or metallic silver inks to expand the colour gamut and push application possibilities even further, making it ideal for operators who require accurate brand spot colours. The new SureColor SC-S range is energy efficient and delivers fast drying graphics with high abrasion resistance and prints that are durable outdoors for up to three-years without lamination.

The products come with a two-year warranty and extended warranty options are available. Users can also take advantage of the Epson SureColor Academy for training, useful tips and tricks, plus ongoing support and access to a wide range of regularly-updated media profiles.

In the UK and Ireland, the SureColor SC-S printers are supplied with an Onyx RIP as standard and are compatible with a wide range of other RIPs.

Pricing and Availability

The SureColor SC-S60600 and SC-S40600 replace the SC-S50600 and SC-S30600 models respectively and are available immediately priced from £9,995 + VAT RRP. The SureColor SC-S80600 replaces the SC-S70600 and will be available to buy from March 2016 priced at £16,135 + VAT RRP (10-colour).

For more information visit www.epson-europe.com

[Image captions: Top - New Epson printers launched at the prestigious home of the Mercedes Petronas F1 racing cars, which are sponsored by Epson; Middle - The top of the range SCS 80600 will be launched in March 2016; Bottom - The new, entry-level SCS 40600 and its sister SCS 60600 are available immediately.]

-

Photobox chooses five new-generation Epson Surecolor SC-S60600 printers to boost photo canvas production capacity

18 Jan 2016

PhotoBox has invested in five new-generation Epson SureColor SC-S60600 64-inch wide-format printers. The company has installed these alongside its existing fleet of 16 SureColor SC-S50600 printers in its UK factory to meet the ongoing growing demand for personalised photo canvases.

PhotoBox is Europe’s leading B2C personalised photo based printing company which puts its considerable success down to inspiration supported by the right combination of product, service, marketing and innovative technology.

Launched in 2000, today the PhotoBox Group encompasses seven brands – PhotoBox, Moonpig, Hofmann, PaperShaker, Sticky9, posterjack and PosterXXL – and employs about 1,000 people worldwide. Its five factories around the world turn digital photos into over 600 different personalised products - including photo canvases - for 30 million members across 20 countries.

James Lawrence-Jones, Group Technical Innovation Director at PhotoBox, is responsible for product and production processes. “Since 2013 demand for photo canvases has grown by 70% year on year and we have expanded our production facilities to keep pace and deliver the very best quality and service to our customers,” says James. “We wanted an ink-efficient printer that would deliver great quality at higher speeds and with maximum reliability and the new SC-S60600 ticks all the boxes. Our manufacturing challenges are unusual because we have to be able to print, finish and despatch a large number of canvases on a day, over 12,000 individual canvases a day 24/7 at Christmas for example, and we have to rely on the very best production equipment to meet our high quality standards and tight deadlines.”

The new, robust SureColor SC-S60600 roll-to-roll printer has been designed to meet the needs of demanding production environments where maximum quality and reliability are key. It uses Epson PrecisionCore permanent printheads in a dual CMYK configuration to deliver outstanding 1440 x 1440 dpi resolution and speeds up to 95.3sqm/hr (single pass) and 52.3sqm/hr (typical banner applications). The sophisticated media feeding system incorporates highly-advanced auto-tension control and wide-diameter pressure rollers to optimise grip and feed accuracy. As a result, operators can load a 45kg roll of media and leave it to print unattended with the confidence that the end result will be perfect.

Very quickly after installation of the new printers, James and his production team were experiencing the benefits. “The SC-S60600 delivers improved print quality at reduced pass rates and offers improved ink efficiency which, when combined with the almost 20% boost in print speeds, results in lower overall production costs,” he says. “The new automated maintenance feature is another benefit,” says James. “It maximises printer uptime and frees up our operators to focus on other tasks to keep the print room running at peak efficiency. Plus, the new improved media loading means accurate media set up is easier and quicker - which allows for long run, unattended printing with the confidence that quality will be consistent across all the images.”

Canvas printing at PhotoBox is a highly streamlined operation. Customers have a choice of three canvas grades, 17 different sizes up to 30 x 40 inch, and rectangular, square and panoramic formats. Images received online on any of the 18 localised websites are automatically nested prior to printing in full-roll batches on a SureColor printer. The rolls are then loaded onto an Esko Kongsberg cutting table, automatically cut to size and finished. The complete process – from order receipt to despatch – typically takes less than 24 hours!

“The SureColor printers are excellent and we work them hard around the clock producing stunning images for our customers. It’s a high stress environment and we need maximum production uptime so when we need it we have great support from Epson and Rockwell, Epson’s appointed service provider,” says James.

Several staff members have also attended the Epson SureColor Academy to ensure they get the best from their printers. “Quality is key for production whatever the time of year so we train our production staff all year round to ensure we’re ‘match fit’ ahead of peak. Our operators have gained a better understanding and expertise in getting the very best results from the SureColors,” says James.

“We have developed the new SureColor SC-S60600 printer to meet the quality, productivity, reliability and efficiency needs of demanding, high-volume customers, such as PhotoBox, and their experience confirms that this new model truly is a superb professional production printer,” says Richard Barrow, Senior Product Manager, Epson Europe.

-

GPT to host HP Open Day in Nottingham

17 Jan 2016

Graphic Printing Technologies (GPT) has announced an Open Day, specifically focusing on HP's range of Latex and Flatbed printers.

-

Epson announces 64-inch 'super-fast' SC-P20000 printer for production market

15 Jan 2016

SureColor SC-P20000 combines the highest quality at print speeds of up to 17.5sqm/hr.

-

World Wrap Masters competition powers up in Amsterdam

14 Jan 2016

FESPA partners with Avery Dennison and Mimaki for the World Wrap Masters Series Final.

-

World Wrap Masters competition powers up in Amsterdam

14 Jan 2016

FESPA partners with Avery Dennison and Mimaki for the World Wrap Masters Series Final.

-

New Mimaki TS500P-3200 to target home furnishing textiles and indoor soft signage markets

13 Jan 2016

Mimaki will be launching its new TS500P-3200 super-wide format inkjet printer in February 2016. The 3.2m-wide roll-to-roll sublimation inkjet printer is a dedicated transfer paper printer for the textile industry and is ideal for a broad range of applications including home furnishing textiles and indoor soft signage.

Exclusively distributed in the UK and Ireland by Hybrid Services Ltd, the Hybrid's National Sales Manager for Textile & Apparel, Stephen Woodall, says: “We’re seeing the trend for on-demand textile printing develop from the fashion and sportswear markets into the interior décor and home furnishing sector. The benefits of digital print enable companies to deliver variable content in varying run lengths with very short lead times; thus capitalising on the technology.”

He continues: “Personalisation works best when coupled with short lead times for the consumer, so another key factor is having a print operation located geographically close to its market, thus bringing manufacturing back to the UK & Ireland.”