Electronics For Imaging, Inc. has announced the availability of the next generation of its industry leading Fiery production printing platform. Digital front ends (DFEs) based on EFI Fiery FS300 Pro platform drive presses across sheetfed, high-speed continuous feed, B1 folding carton, and corrugated digital production systems. These new products retain Fiery technology’s position as the world’s most productive and versatile DFE platform offering with new features in the key areas that print customers care about: colour, performance, usability and integration.

“With the trend toward shorter runs and faster turnaround times, digital print shops need systems that make every minute and every step count. Shops can double the processing speed on more types of jobs with Fiery HyperRIP enhancements on the Fiery NX Premium print server,” said John Henze, vice president of marketing at EFI. “Higher Fiery processing speed enables 10x the throughput than before on Fiery XB print servers, driving print engines all the way to 2,400 ppm and beyond.”

The Fiery FS300 Pro platform comes with the new, free Version 6 of Fiery Command WorkStation, the most popular production print job management solution in the industry, estimated to be used by more than a quarter million print professionals.

Fiery Command WorkStation: more productive than ever

The Fiery FS300 Pro platform is accompanied by a completely redesigned Command WorkStation that dramatically improves the industry’s most trusted job management application. In less than two months, more than 41,000 have already upgraded to the new version to run their print shops more productively.

“It was an easy transition to Command WorkStation 6,” said Dan Moore, print operator, Star Digital Print in Lincoln, Nebraska. “As soon as we upgraded, we realised we can find specific jobs faster with the new search tools. We have an overall faster experience interacting with jobs and working with presets and templates to automate our workflows and keep our engines busy. We’ve found Command WorkStation 6 to be a reliable and robust way to manage print jobs across our three print engines.”

Another company using the software, New Delhi, India-based Avantika Printers Pvt. Ltd., produces more work per shift thanks to the Command WorkStation 6’s strengthened search features. Himanshu Pandey, director of Avantika Printers in Delhi, India, “The transition to Command WorkStation 6 increased the productivity of Avantika’s shop floor by 15%.”

Version 6 features a number of productivity enhancements, including:

• The ability to manage a variety of printers across the production operation by connecting to Fiery Driven™ cutsheet, high-speed inkjet presses, and, in 2018, wide- and superwide-format printers.

• Previews for all jobs and new search tools that provide faster ways to interact with jobs. Job views can also be customised to specific needs, such as by media, to help prioritise print production.

• The ability to reprint a job faster and more consistently by using saved rasters on already printed jobs.

• Home, a new view in Command WorkStation 6 that provides at-a-glance status of all connected Fiery servers and a snapshot of key print production statistics.

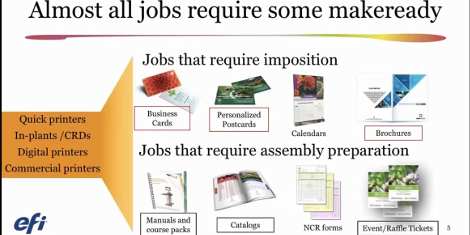

• New versions of Fiery Impose, Compose and JobMaster™ fully integrated and accessed directly through Command WorkStation, which enables users to produce high-value print products more profitably, in less time and with fewer clicks. Imposition layout is simplified and users can more easily create gangup layout templates to automate job imposition which can turn a 10-minute job preparation into 10 seconds.

Uncompromising colour out of the box

As with previous Fiery generations, the FS300 Pro platform places significant emphasis on delivering outstanding colour out of the box while also offering tools for expert interaction with the system.

The Fiery FS300 Pro platform features easy prioritisation of spot colour edits on a job basis to satisfy customers’ specific colour preferences.

Fiery ImageViewer enhancements include Object Inspector and Total Area Coverage features that help identify imaging problems related to particular object types. Operators can diagnose and troubleshoot colour problems without going back to the source files, savings hours in turnaround time to get jobs out.

“Keypoint Intelligence’s software investment surveys have consistently told us that workflow automation, managing shorter runs, and capturing shop floor data to use in business decisions are key areas of interest for print service providers,” according to industry analyst Pat McGrew, Production Workflow Director, Keypoint Intelligence. “With the Fiery FS300 Pro and the new Command WorkStation, EFI is responding to what printers want most from their DFEs.”

The Fiery NX Station: advanced design for high productivity

The new Fiery workstations feature a compact, ergonomic design that has the comfort of the operator in mind and requires 20% less floor space than previous generations. The height of the NX Station LS work surface adjusts by six inches (15 cm) for optimum user comfort. The LS workstation’s proximity sensor automatically displays Command WorkStation when the operator is near. In addition to the LS workstation’s large, adjustable 27-inch monitor, Fiery NX servers include a unique 7-inch touchscreen display, with Fiery QuickTouch software that provides fast views of job status information and access to server management.

“These enhancements just scratch the surface of what users will see with the new Fiery FS300 Pro platform and Command WorkStation 6,” EFI’s Henze added. “The first implementations by our partners will be at Print 17, September 10-14 at McCormick Place in Chicago. Visitors to EFI’s booth 2302 at the show will get an in-depth view of how Fiery FS300 Pro and Command WorkStation 6 can fuel business growth through increased productivity, profitability and print quality.”