SCREEN will demonstrate the capability and flexibility of the latest high-speed 150sqm/hr Truepress Jet W3200HS UV flatbed printer at FESPA 2015 (Stand U20/Hall 6, 18-22 May in Cologne). Plus, for the first time worldwide, visitors will see the new 3.2m wide roll-to-roll option which turns the Truepress Jet W3200UV into one of the industry’s most versatile machines capable of handling a variety of flexible and rigid materials.

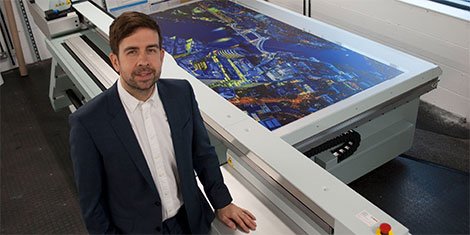

A joint development between SCREEN and its subsidiary company Inca Digital, the Truepress Jet W3200UV printer is a six colour + white device designed to meet the demands of the POS, signage and decor markets today. It has the ability to print onto a wide range of rigid and flexible media up to 3.2 x 1.6m in size and up to a maximum 50mm thickness. Using vibrant Truepress inks including high-opacity white, light cyan and light magenta, the Truepress Jet W3200UV delivers high-definition, wide-colour gamut print quality with excellent resistance to the bending and cutting of a variety of print substrates. To ensure maximum quality, reliability and production uptime, the printer features automatic cleaning and nozzle mapping.

During the show SCREEN will print a variety of challenging graphics so visitors can see the printer’s ability to produce smooth tints, vivid colours and sharp 4pt text. The aim is not only to demonstrate the printer’s significant 150 sqm/hr productivity at great quality, but also how easy it is to print high-value products, including 5 and 7-layer multi-layer backlit and day/night graphics and accurate 75lpi lenticulars at over 50sqm/hr.

The Truepress Jet W3200UV is available in both standard (85sqm/hr) and high-speed (150 sqm/hr) versions and users can easily upgrade from standard to high speed as the needs of their business grows. Both models are supplied as standard with the Caldera GrandRIP+, including the EasyMEDIA option for ICC profiles. Integration to a range of other workflows is also available.