3M has combined the 3M Scotchcal Graphic Film Series IJ40 with the new Scotchcal Over-laminate 8019/8020 to provide a more competitive integrated graphics solution. This latest offering again demonstrates 3M’s ability to meet a wider range of customer needs, including high-performance products at an accessible cost

Scotchcal Graphic Film Series IJ40 is a five-year polymeric film that is available in either a gloss or matte finish and with a permanent or removable pressure-sensitive adhesive, with or without 3M Comply air release technology. The majority of films feature a grey, pigmented adhesive that offers excellent hiding power for applications requiring this particular performance enhancement. Scotchcal Over-laminate 8019/8020 is a transparent polymeric laminate material, also available in either a gloss or matte format, with a pressure-sensitive adhesive. Both films can be converted using solvent-based piezo inkjet printing systems and are covered by the renowned 3M MCS (Matched Component System) Warranty for appropriate intermediate applications.

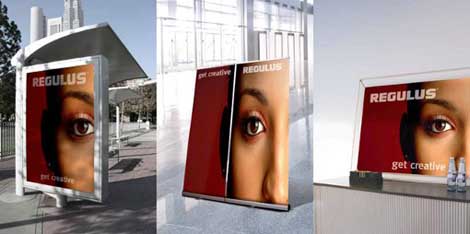

This new integrated graphics solution can be used for a range of diverse applications involving flat or gently curved surfaces, including vehicle fleet and window graphics, interior and exterior signage and backlit signs and displays. The solution is available from 3M primary distributors William Smith and Spandex.

3M, Scotchcal, Comply and MCS are trademarks of 3M Company.

For further information, please visit www.3M.co./uk/graphicsolutions